Outdoor Louvered Composite Shutters

-

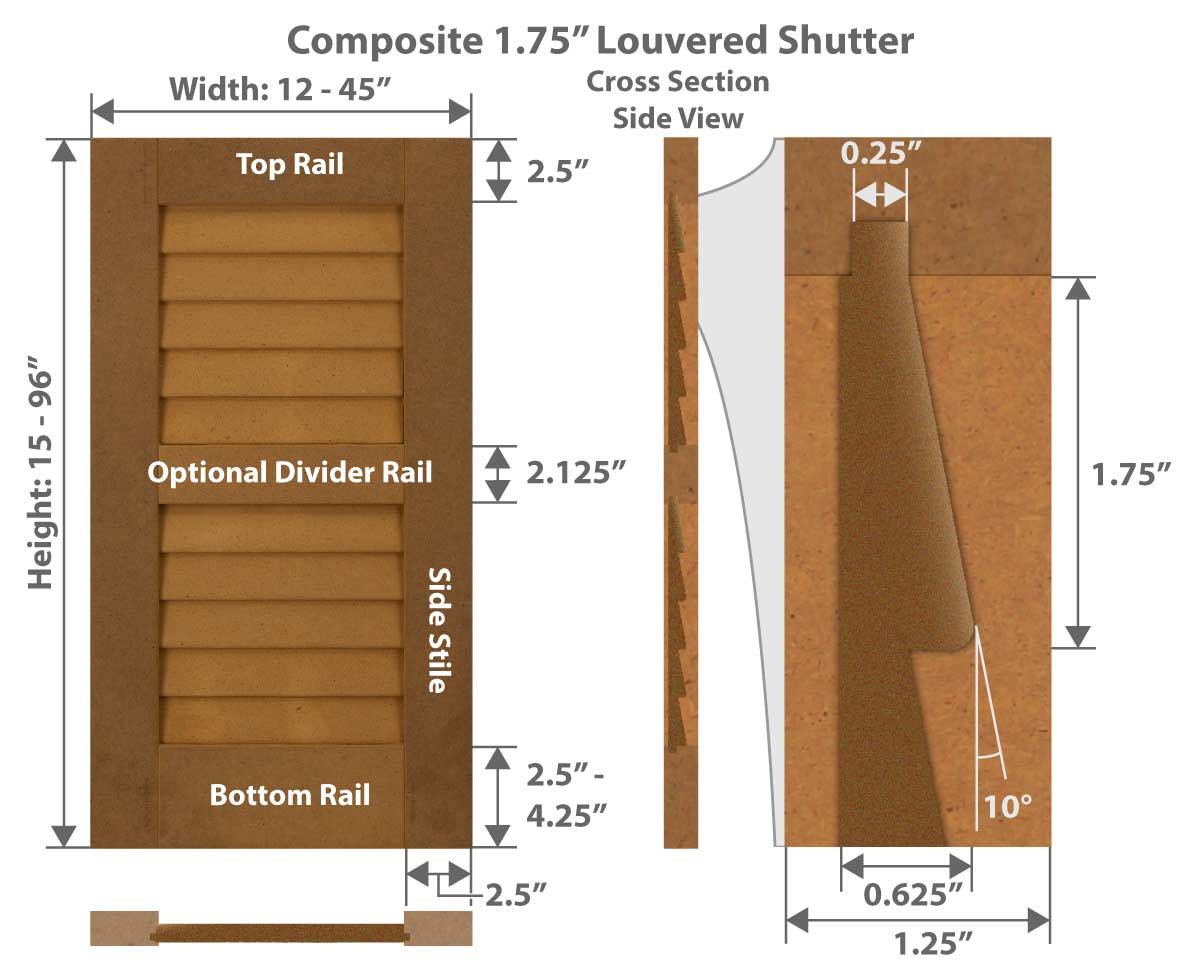

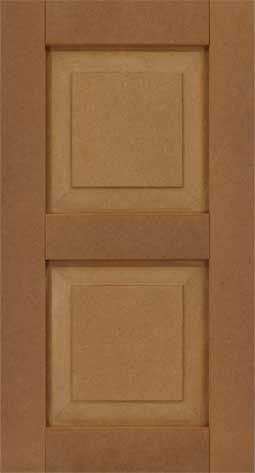

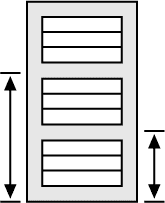

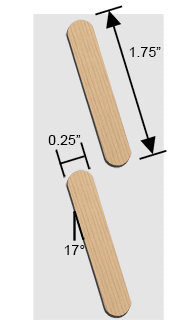

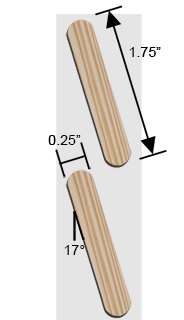

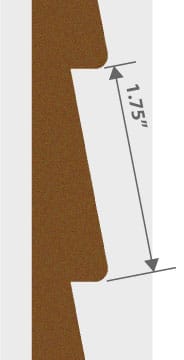

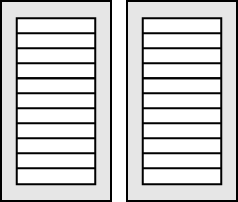

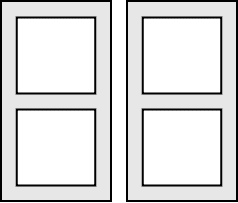

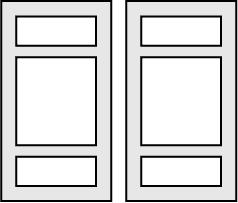

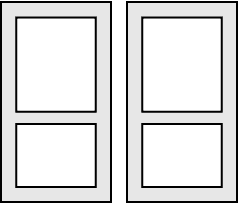

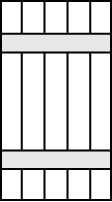

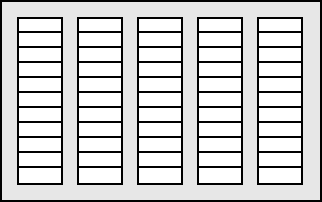

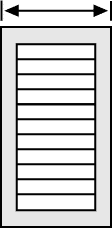

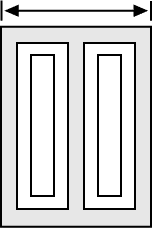

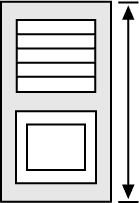

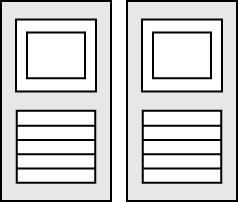

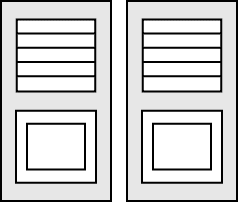

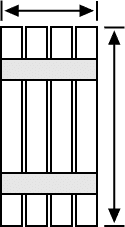

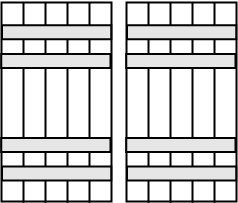

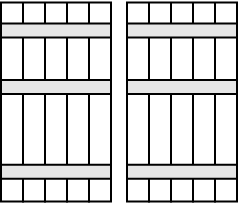

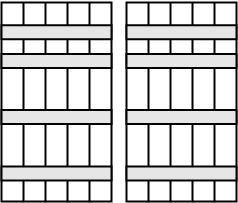

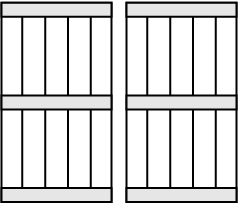

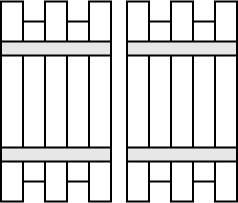

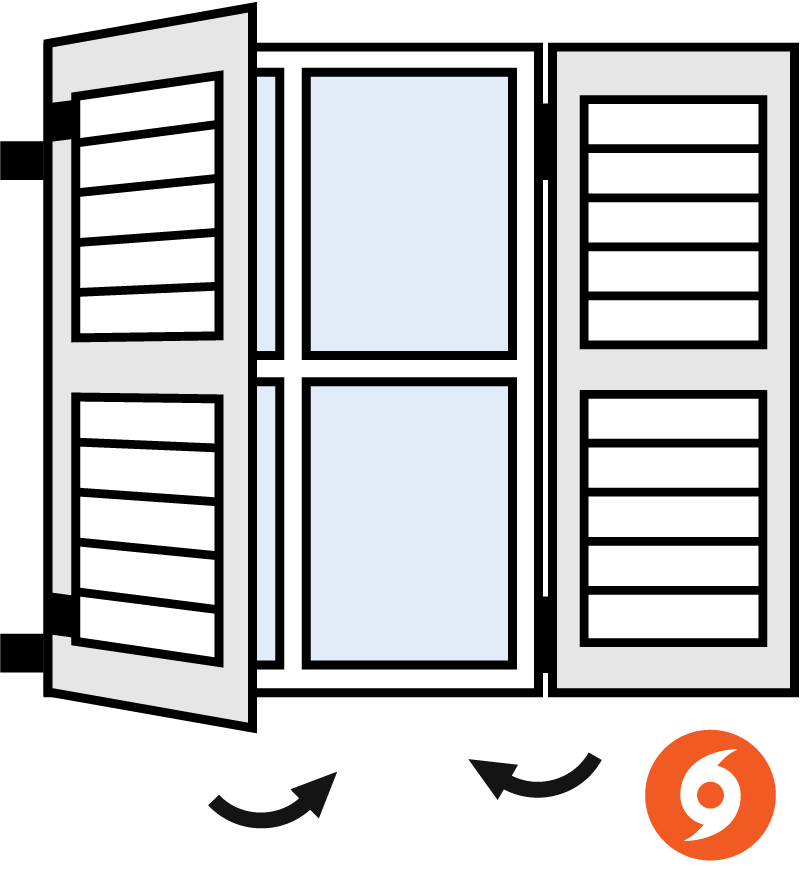

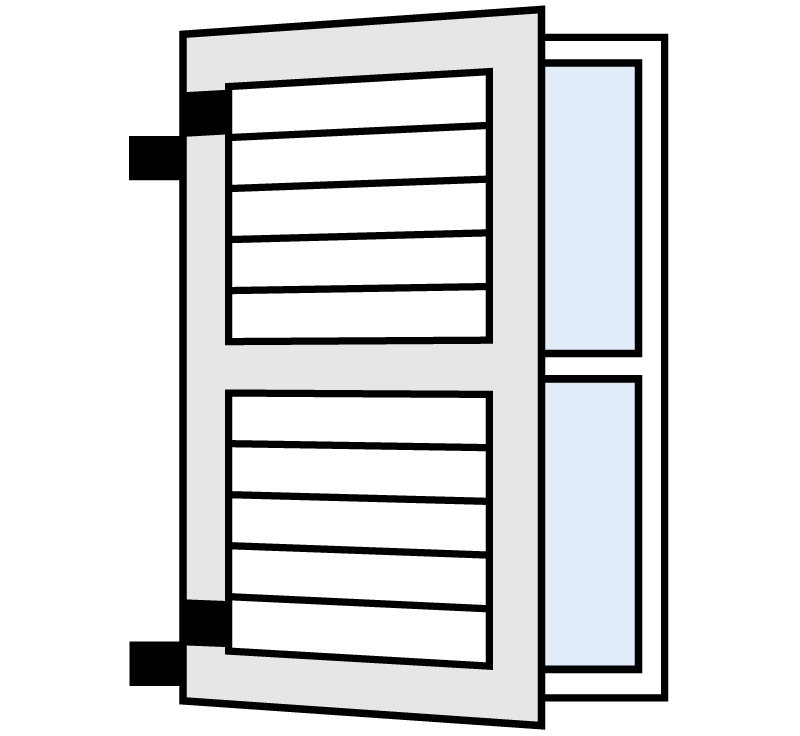

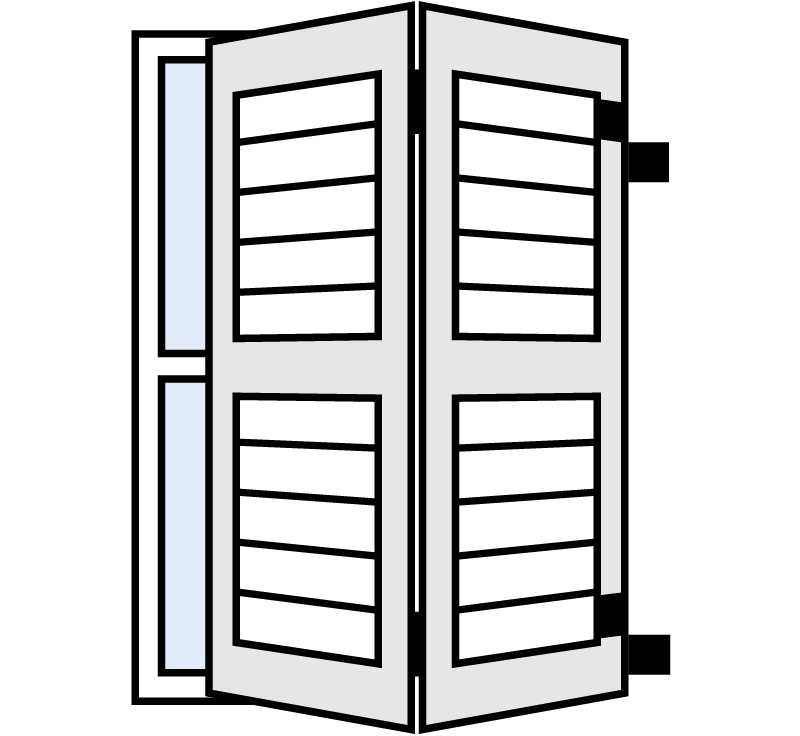

Composite shutter with divider rail & 1.75″ louvers

-

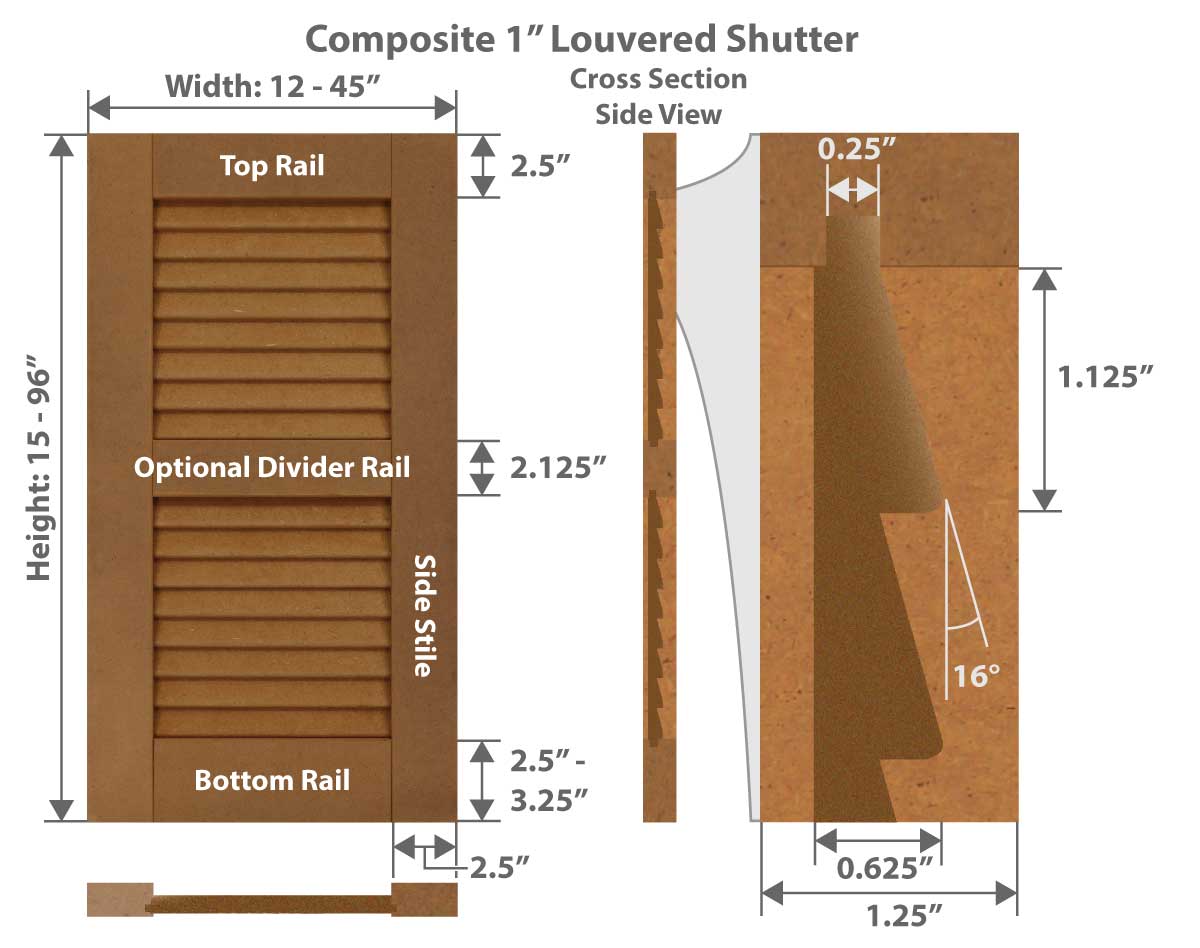

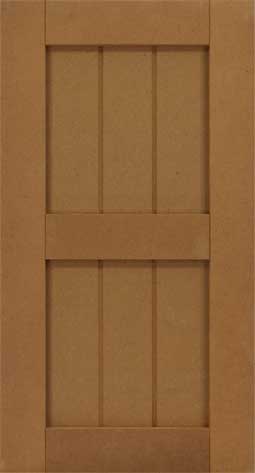

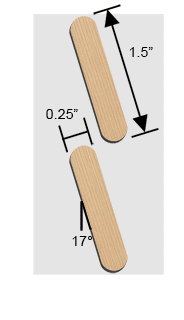

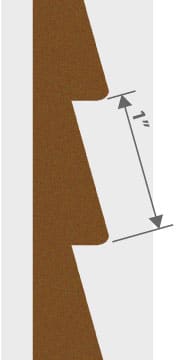

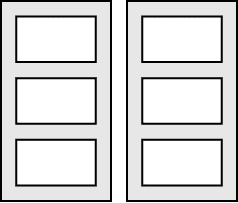

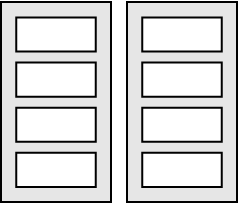

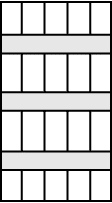

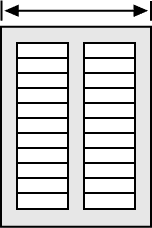

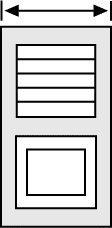

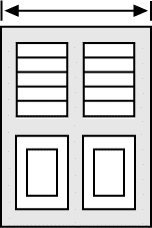

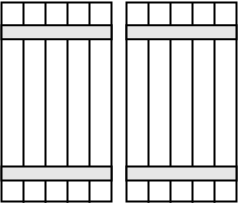

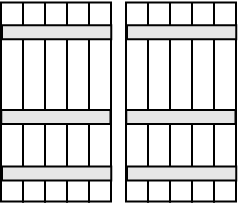

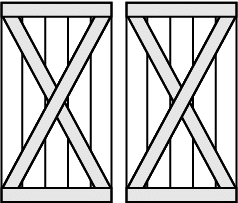

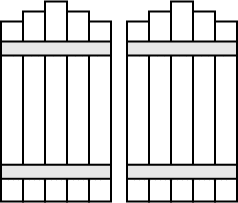

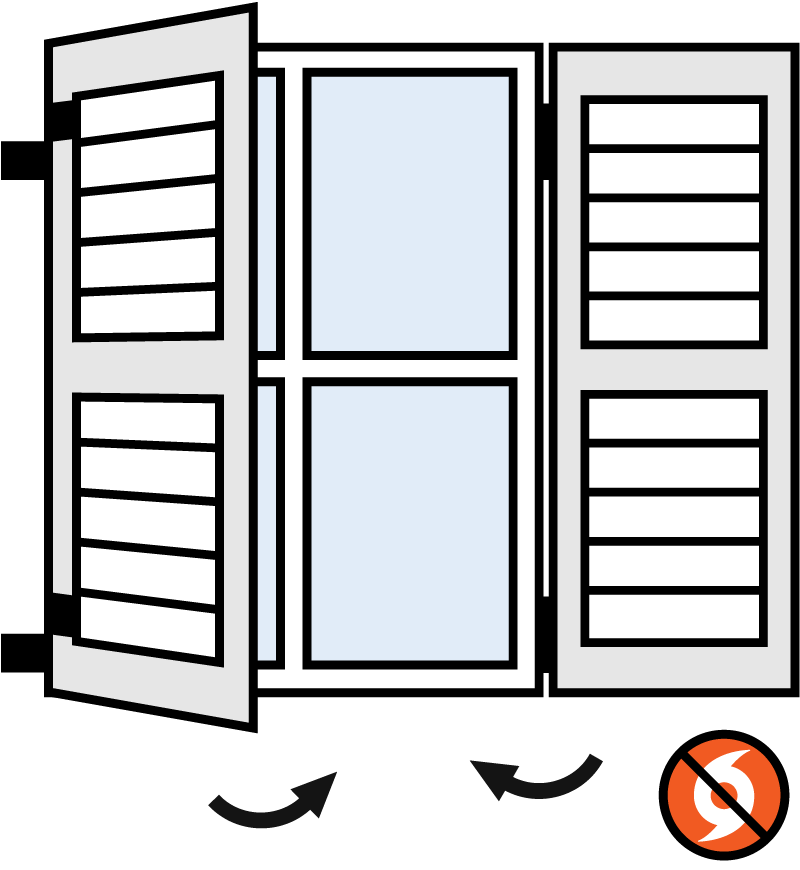

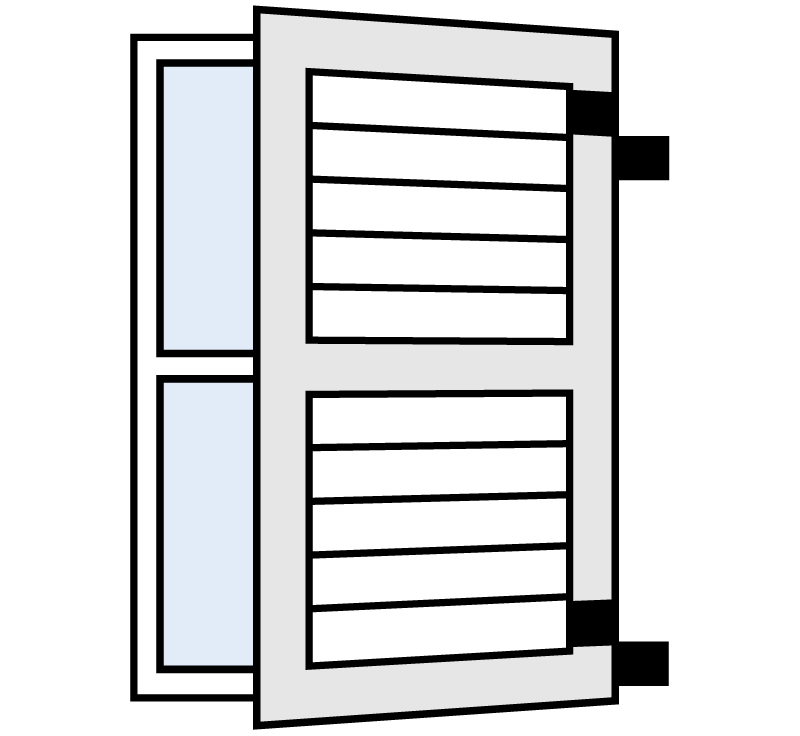

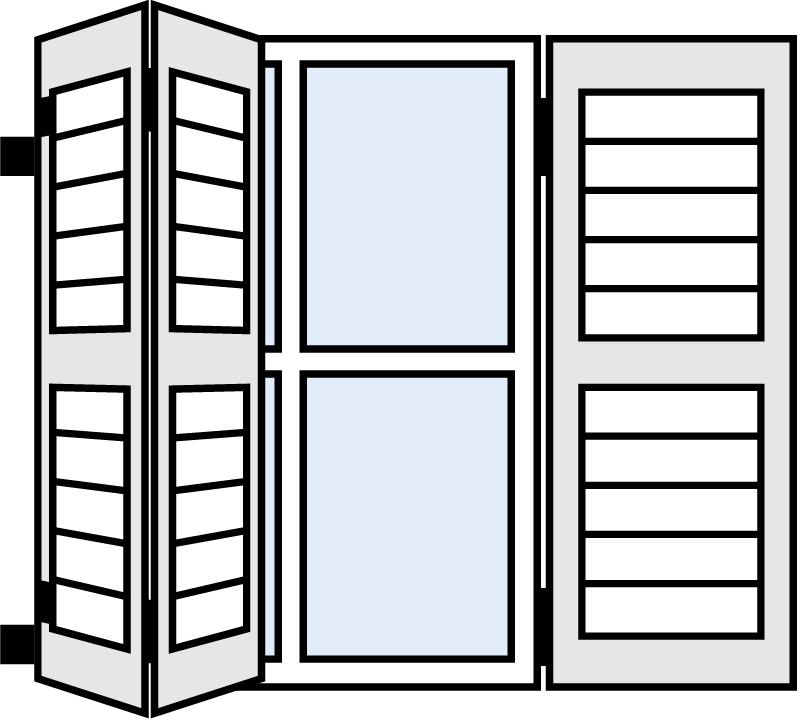

Composite shutter with divider rail & 1″ louvers

-

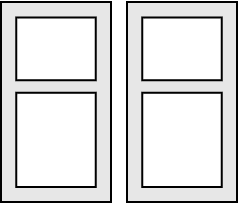

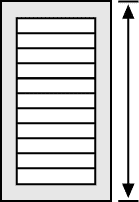

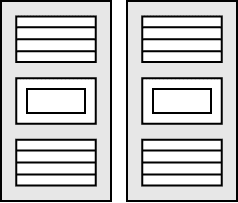

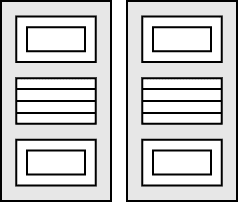

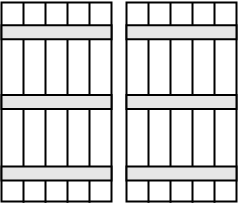

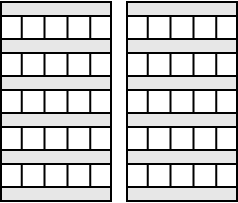

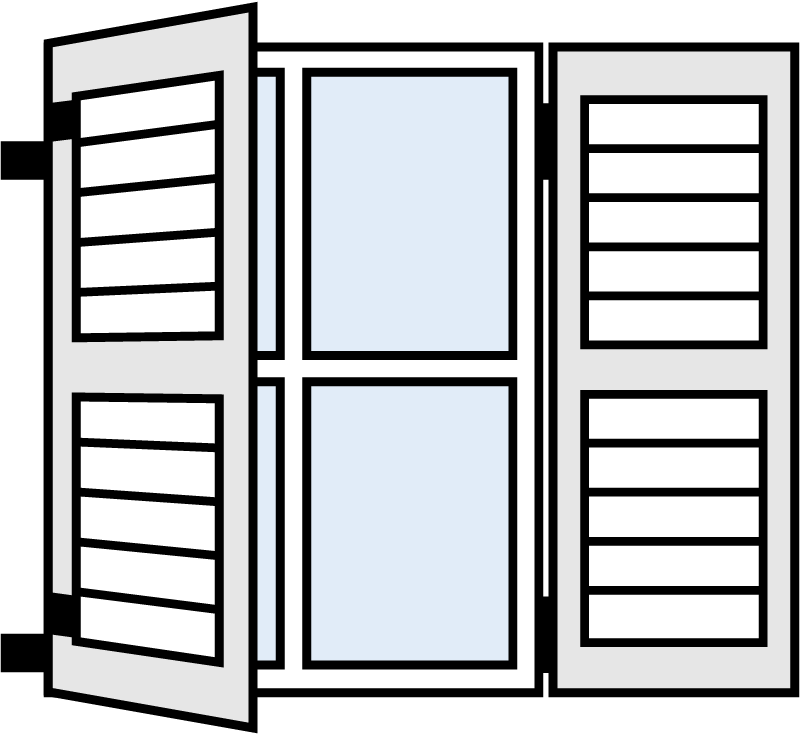

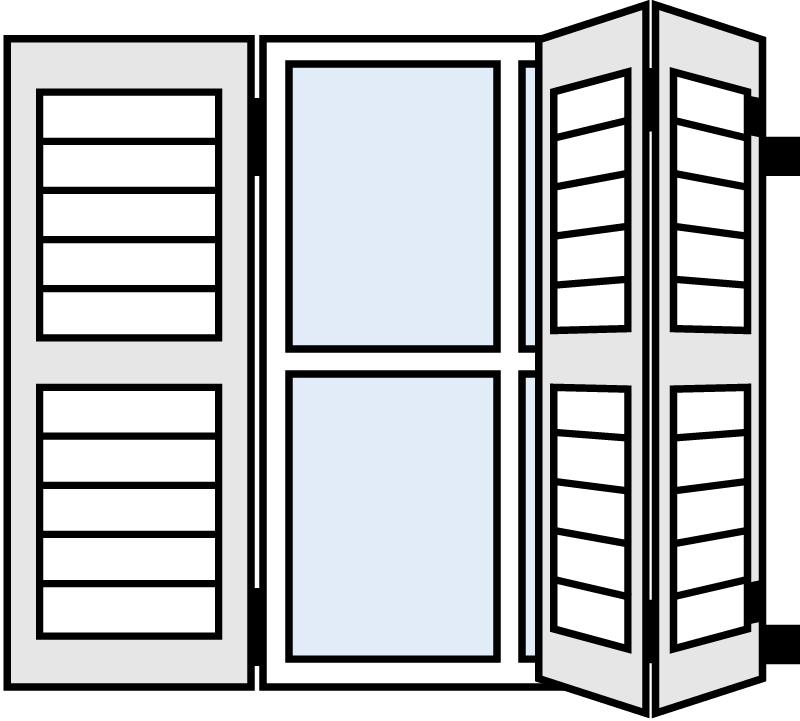

Composite shutter with divider rail & 1″ louvers

-

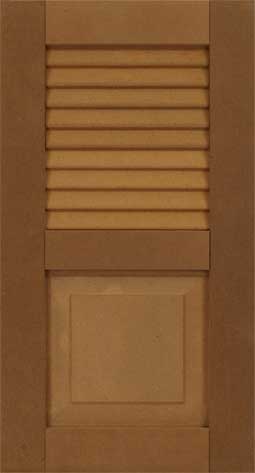

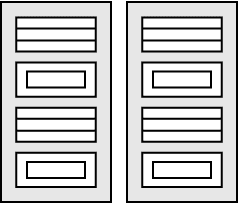

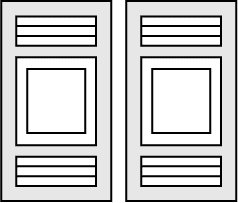

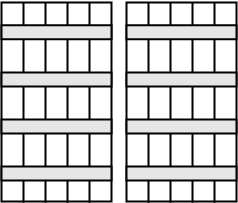

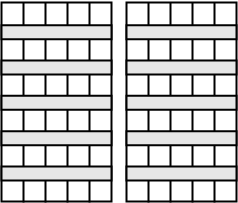

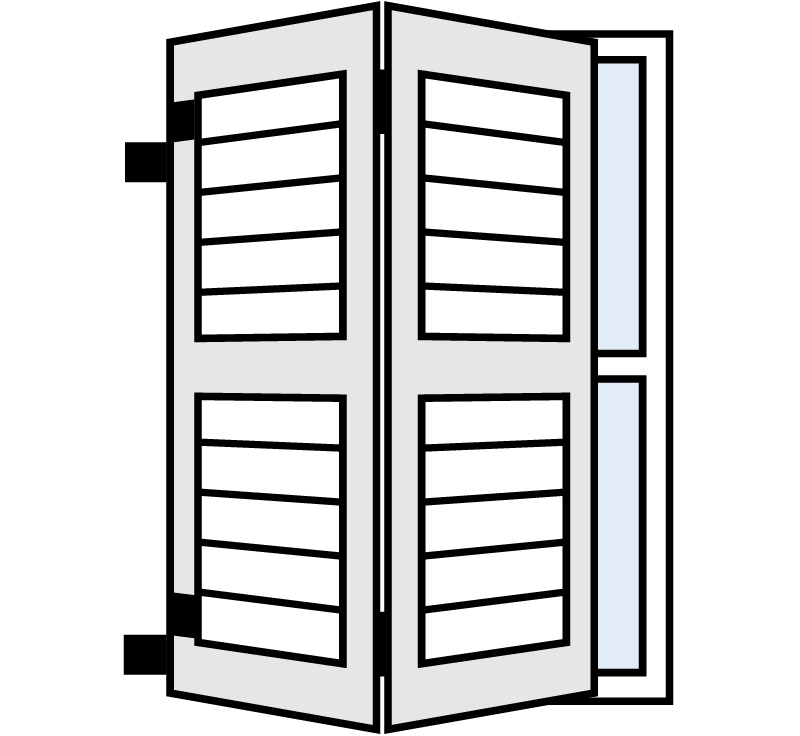

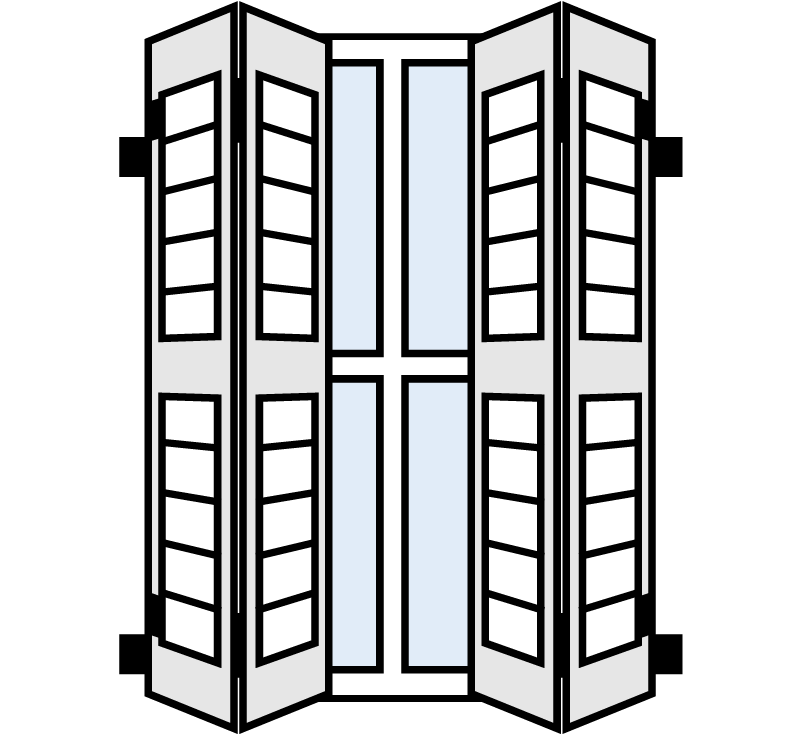

Composite shutter with 1″ louvers zoom

-

-

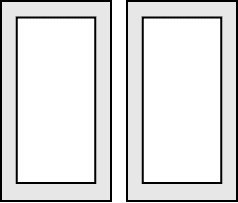

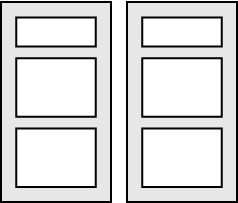

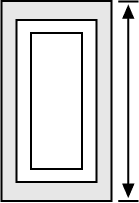

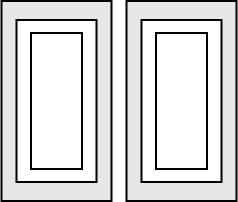

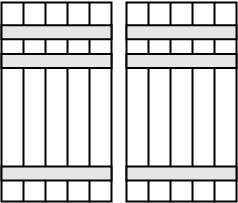

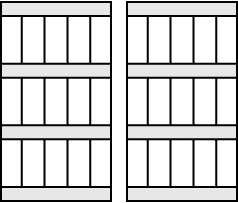

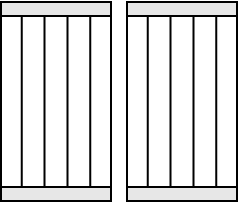

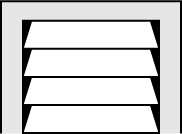

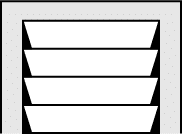

Composite shutter without divider rail

-

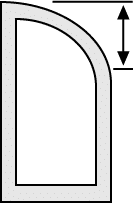

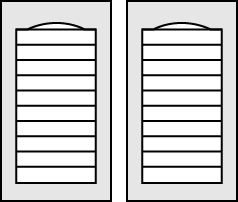

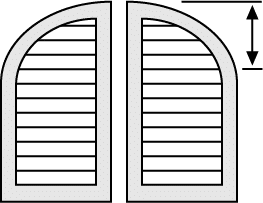

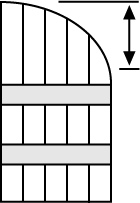

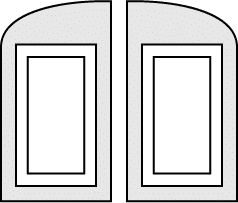

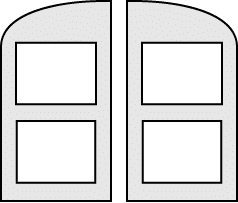

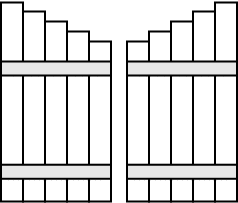

Arch top composite shutter with 1″ louvers

-

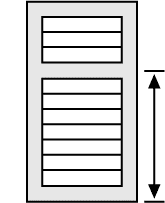

Composite shutter with 1″ louvers and tilt bar

-

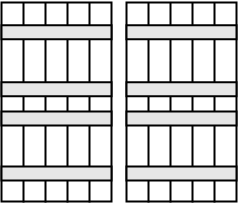

Composite primed shutter 1″ louvers

-

Painted composite louvered shutter installed

Description

Louvered composite shutters are designed to resemble the distinct profile of wood louvered shutters. Outdoor composite shutters are constructed from Extira, a solid pressed durable material. It is virtually impervious to moisture, rot, and termites, insuring an extremely long life. Unlike wood shutters that use multiple slats, composite louvers are shaped from a single piece with no space between louvers. Louvered composite shutters are installed in a stationary position because they have only one presentable side.

read more

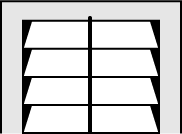

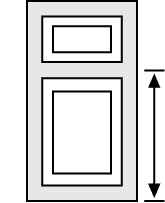

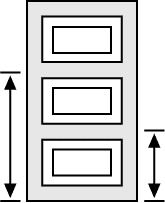

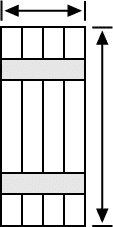

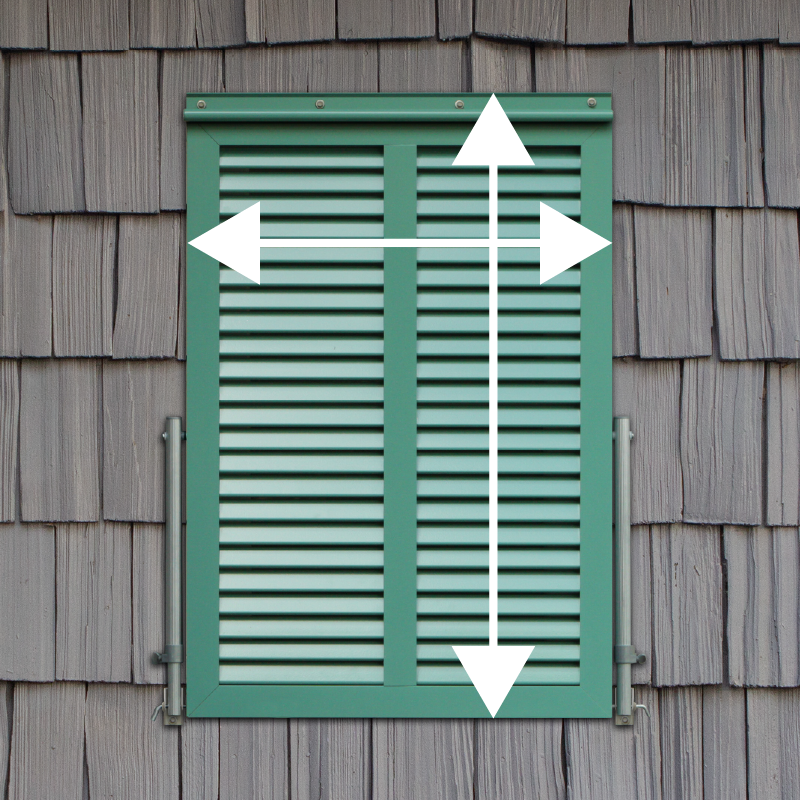

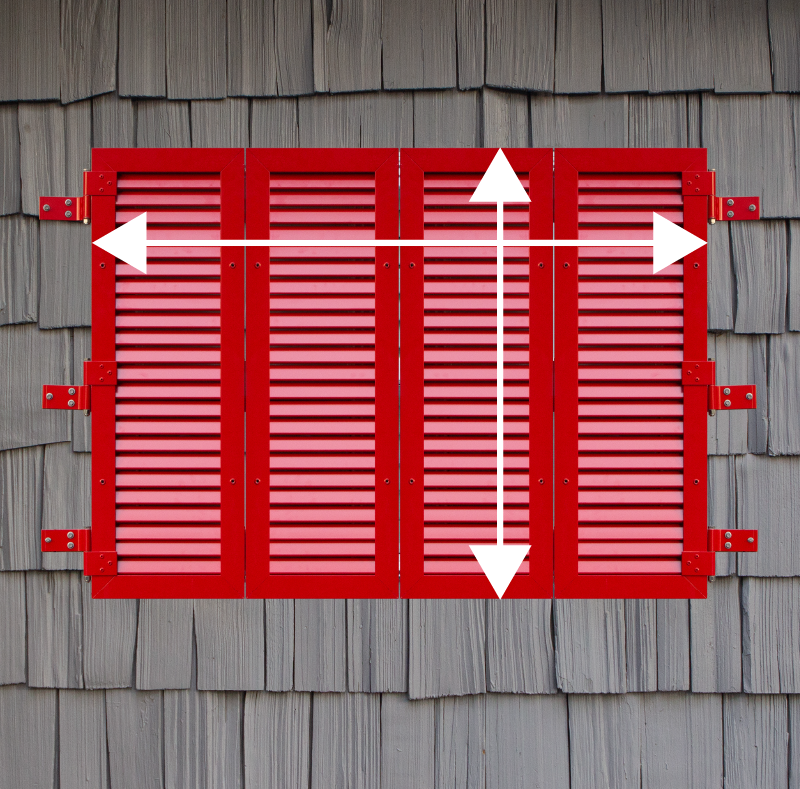

Dimensions

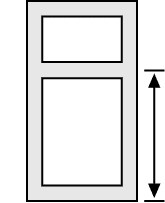

-

Width

12 – 45″ in 0.25″ increments

-

Height

15 – 96″ in 0.25″ increments

-

Louvers

1.75″ louvers

Fixed 10° angle

Calculate number

No space between louvers

Stationary (Fixed down)

-

Tilt Bar

Faux only – Optional (+$)

-

Side Stiles

-

Top Rail

-

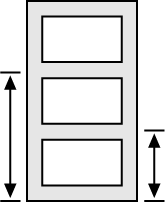

Divider Rail

2.125″ height

Required over 70″

Division Point: Bottom of shutter to center of divider

Second divider rail available

-

Bottom Rail

-

Shutter Depth

-

Spec Sheet

-

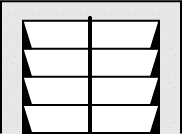

Width

12 – 45″ in 0.25″ increments

-

Height

15 – 96″ in 0.25″ increments

-

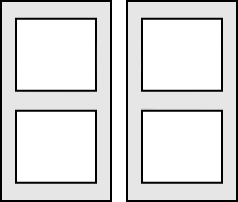

Louvers

1″ louvers (+$)

Fixed 16° angle

Calculate number

No space between louvers

Stationary (Fixed down)

-

Tilt Bar

Faux only – Optional (+$)

-

Side Stiles

-

Top Rail

-

Divider Rail

2.125″ height

Required over 70″

Division Point: Bottom of shutter to center of divider

Second divider rail available

-

Bottom Rail

-

Shutter Depth

-

Spec Sheet

Details

-

Material

-

Finish & Colors

-

Assembly

Tongue & groove joints

Industrial exterior glue

& 1″ staples

-

Top Options

-

Reverse

Back is flat without detail

-

Weight

Approximately 3.2 lbs per sq ft

-

Production

Approximate Time: 4-6 weeks

-

Warranty

-

Measure

-

Install

-

Hardware

-

Thank you for a smooth transaction, I would recommend your services.

G.P.

-

My experience with Shutterland has been outstanding. From order to shipment/delivery to paint prep and final painting all went super. They look great! I …

Norm B.

-

I ordered a set of exterior louvered shutters from Shutterland last fall. I recently had them painted and installed. I wanted to let you know …

Pamela S.

-

Received my order – I have to commend you on the quality and construction of the product made to a standard way above my expectations particularly …

Bill O.

-

I was looking for shutters to replace our original (and rotting) wooden shutters on our home, built in 1942. Comparing materials, prices, and quality, I …

David A.

-

I ordered my shutters online and it was nice to be able to give my custom measurements so that everything was snug for my application. …

Michael A.

-

We are very pleased with the quality of our new shutters. They’re well made; very solid and substantial. Much better than the cheaper vinyl …

Nancy R.

-

We had three sets of shutters that were five years old that began to deteriorate. We ordered the Shutterland shutters with California Redwood to get …

James R.

-

Shutters came as expected, and matched well with the siding color, the roof color and the door. They were solid and very high quality – as …

Ravi S.

-

My experience with Shutterland was good. The shutters were easy to order and arrived within the quoted amount of time. The product arrived exactly as …

Cameron S.

-

We love the final results of our Shutterland flat panel composite shutters. We live in Florida and the constant humidity and wet weather can wreak …

Geoffrey M.

-

We are very pleased with our Bahama shutters we ordered from you. The quality of product as well as service from both Shutterland and House …

Chuck O.

-

The shutters really are beautiful. The painter we are using took one look at them and said “these are the heaviest, most sturdy shutters I …

Doug B.

-

This is my favorite historical renovation yet thanks to your shutters with tilt rods.

Sherri L.

-

We wanted to get the old falling-apart shutters replaced before the holidays, and it was mid September. When I found Shutterland online, I called …

Tom A.

-

We are pleased with the quality, pricing and results achieved with the shutters. Of note, unfortunately we were not aware of your site and ordered …

John Z.

-

We are loving your shutters installed on our historic home in Charleston, SC. BAR approved and looking good! We will order another set for a …

Lani C.

-

My experience with Shutterland.com was very good. The shutters arrived considerably earlier than I expected, and I was very pleased with them. The shutters …

Mark G.

-

The shutters were delivered in a timely fashion. They were exactly like the way they were pictured. We are very pleased with the shutters. We …

Steve S.

-

This was my first time using Shutterland. The company was always professional to deal with and kept me informed of the production timeline throughout the …

Adam D.

-

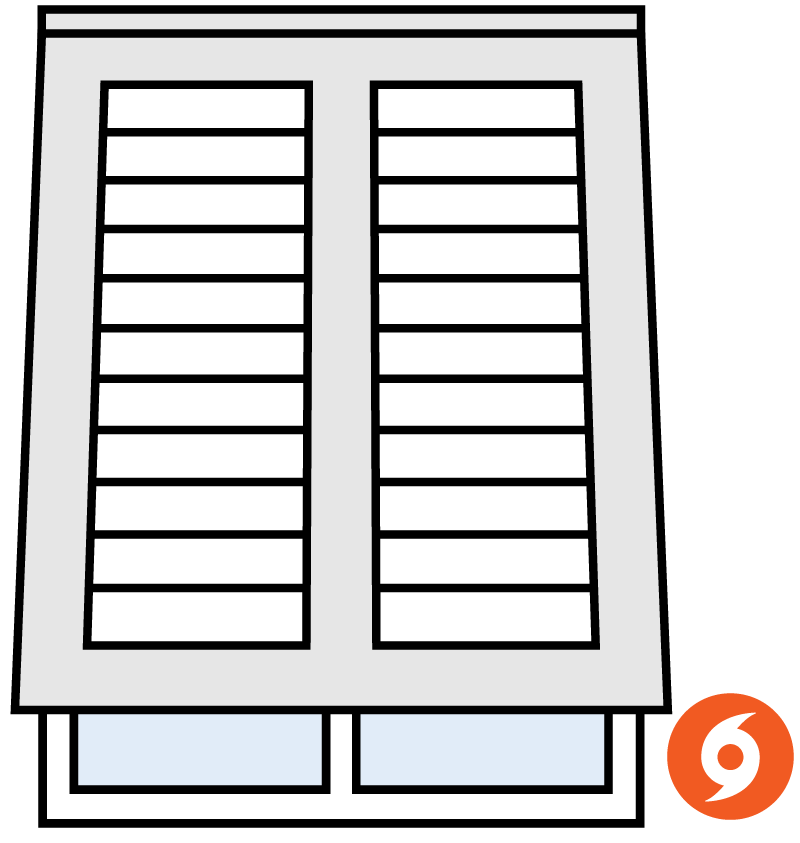

Our house took a direct hit from Hurricane Irma last year when the storm made landfall in our ocean front yard as a Category 4 …

Roy S.

-

I ordered custom size exterior shutters from ShutterLand and they are awesome! They look great and really add to the beauty of our home. Thanks …

Stephen D.

-

We had an excellent experience with ShutterLand. Our shutters were delivered in the time frame we were told and were the proper size and of …

Pam D.

-

My exterior louvered shutters arrived today. Just beautiful!!! I almost hate to have to paint them. They are sturdy, well constructed and much more than …

Joe & Kirsten S.

-

Great selection of sizes and styles of exterior window shutters; easy to order online. Delivery was timely, the quality outstanding. It was a pleasure to …

James B.

-

I was amazed at the quality of your window shutters. It was far superior to any other house shutter material I have purchased. Excellent quality …

Bruce G.

-

The best shutters we have ever had, and I can’t believe we ordered them on the Internet! I have given your web address to …

Caroline N.

-

Wooden exterior shutters are well made and beautiful. I just finished painting them and can’t wait to get them on my house!

Cheryl B.

-

I was so happy to find your company online and you had exactly what I wanted at a good price and excellent workmanship.

Beth K.

-

I would use this source again for outdoor shutters and would also recommend it to others. The price, quality and service were excellent.

Gordon S.

-

Much better than my “in-store” experience. Great exterior shutter selection and prices!

James P.

-

My wife and I recently purchased four cedar shutters from you. They arrived on time and in perfect condition. I just wanted to let you …

Mark H.

-

I had a question about priming the shutters and your representative, Jack, gave me a very quick and useful response on just how to prime …

Neil S.

-

Thank you so much. My wife was blown-away at how nice they look and the color is a perfect complement to our new concrete-…

Tom B.

-

I recently ordered some exterior shutters from your company. I want to tell you how impressed I was with the quality of your work. I …

Paul G.

-

Having checked many sources for good quality combination house shutters, I found ShutterLand to have a good selection with the sizes I needed and excellent …

David F.

-

We are very pleased with the fast service and quality of product; we have had many compliments on our raised panel shutters and are happy …

Lori W.

-

These are the best shutters (quality and price) I have found anywhere.

John R.

-

My experience was great. Thanks.

Roger

-

Being somewhat of a woodworker myself, I was very impressed with the quality of workmanship that went into the shutters. I will no doubt use …

Peter P.

-

I would definitely purchase from Shutterland again!

ShutterLand Customer

-

Shutters were made with excellent, quality materials and delivered undamaged and in a timely manner.

David W.

-

Very satisfactory experience with your company. Well made shutters and good service. Thanks!

Mark G.

-

I just want to say how much I LOVE the shutters I ordered from y’all (yes, I’m from South Louisiana so I don’…

Charlotte H.

-

The shutters arrived Monday, right on schedule. They are SO BEAUTIFUL. I just wanted to stand and admire them. I HATED to paint them. They …

Rebecca T.

-

I have an older home and wanted to keep the authentic look of raised panel outside shutters. The original wood shutters had been painted numerous …

Karen R.

-

The exterior shutter looks like a work of art. The other house shutters that I have are either molded plastic or older wood ones that …

Sparky K.

-

This is the only web site I found that was truly adequate for ordering quick shutters without any other contact. Very convenient.

Allen P.

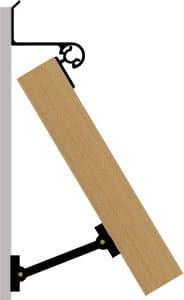

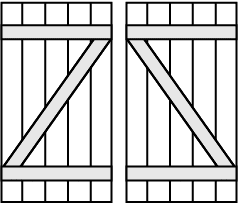

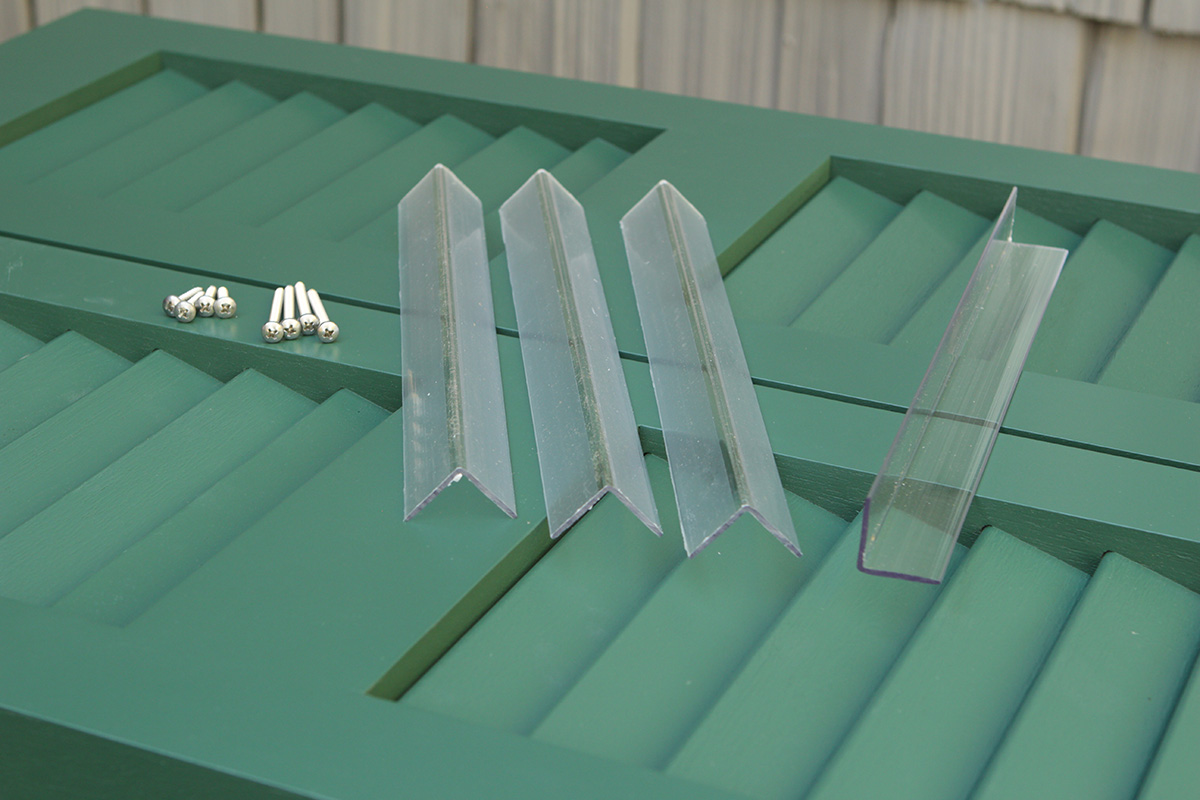

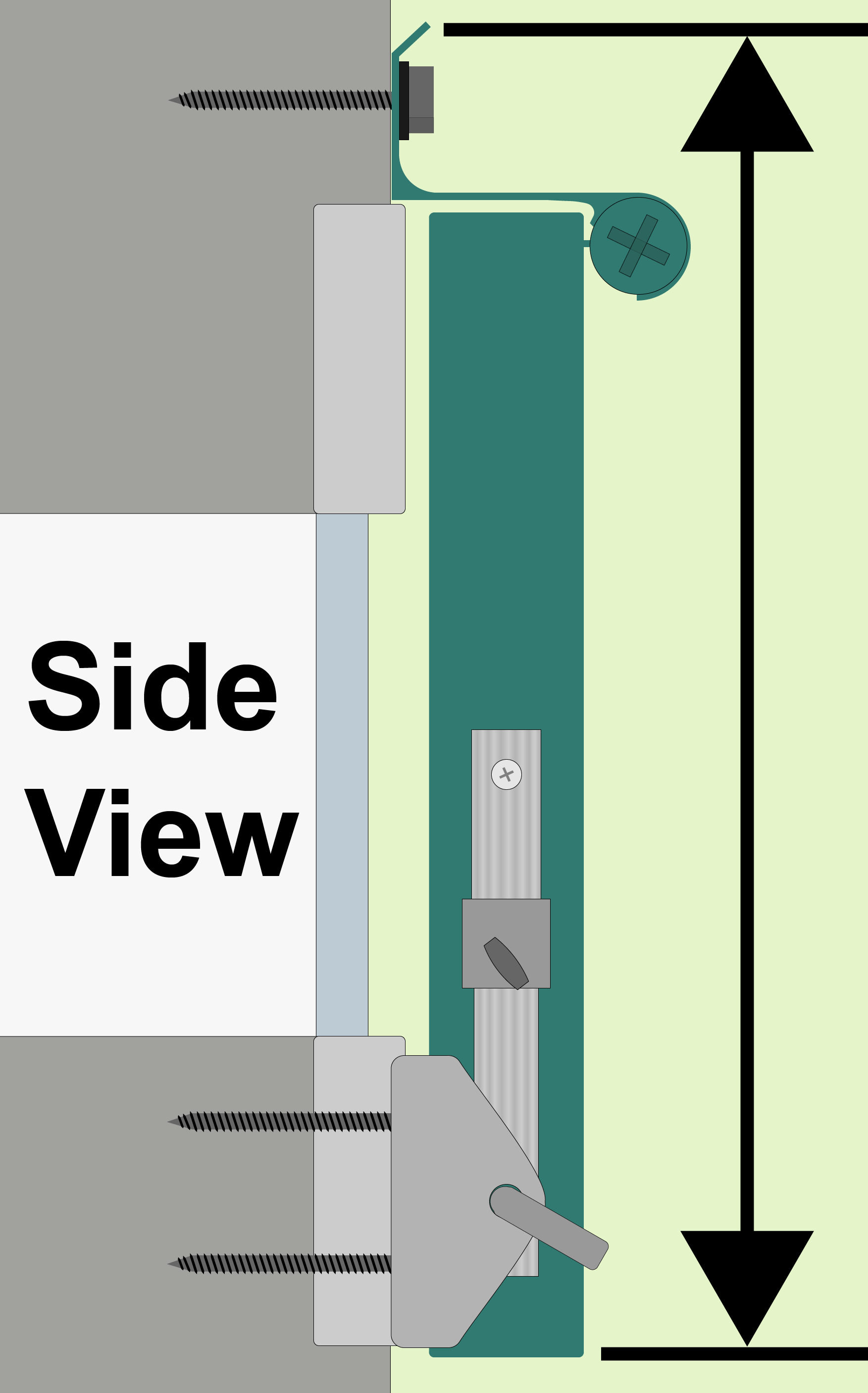

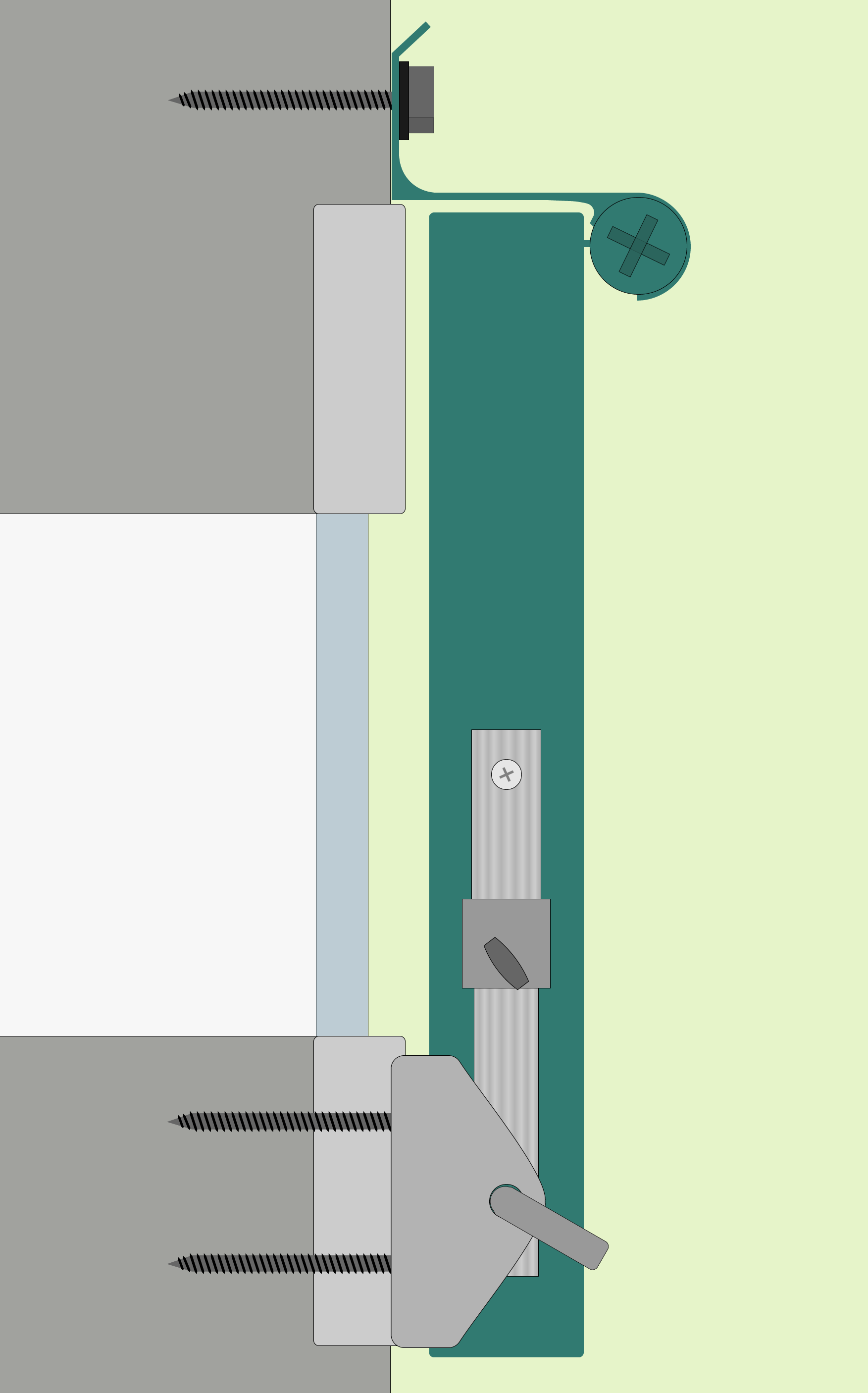

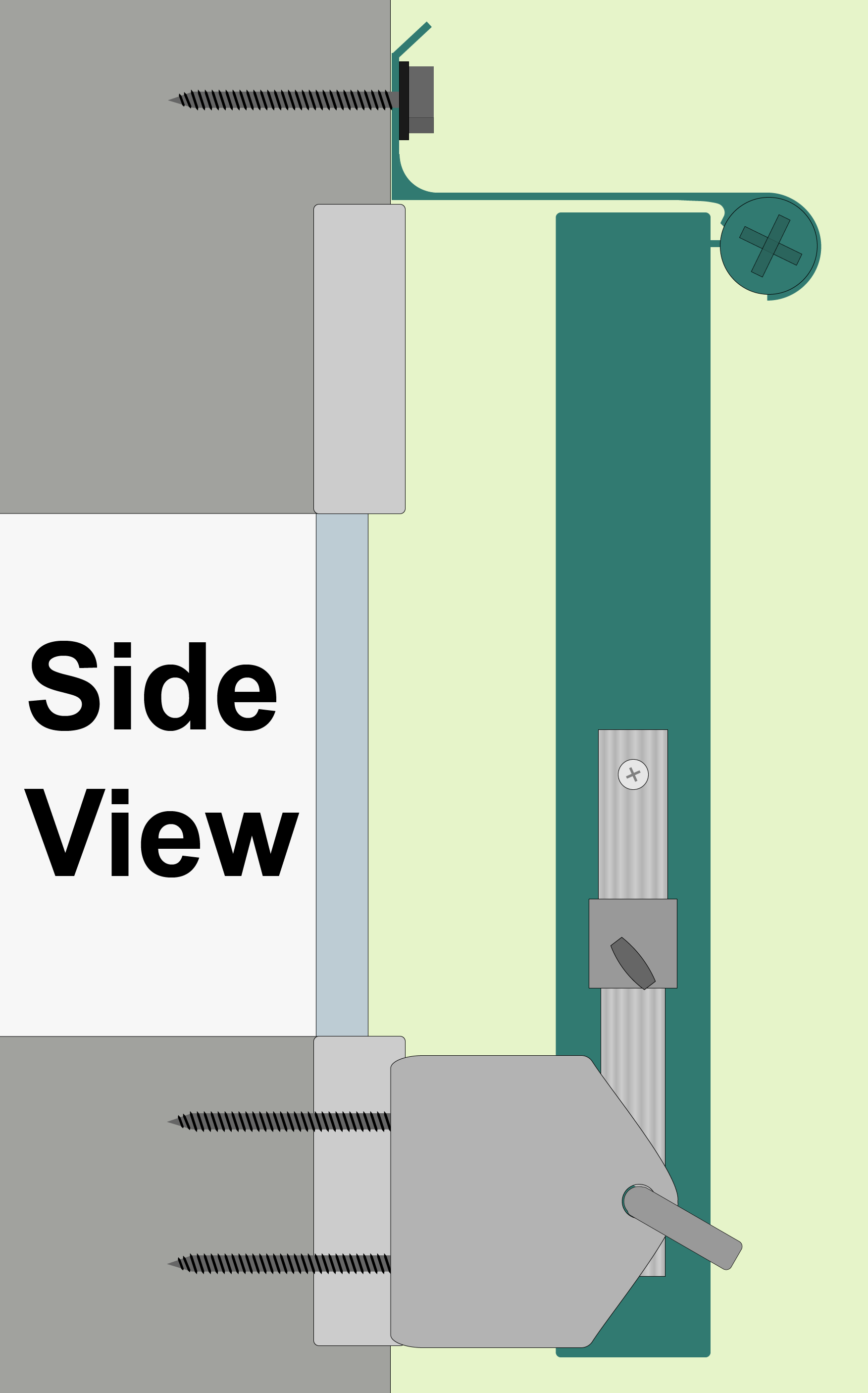

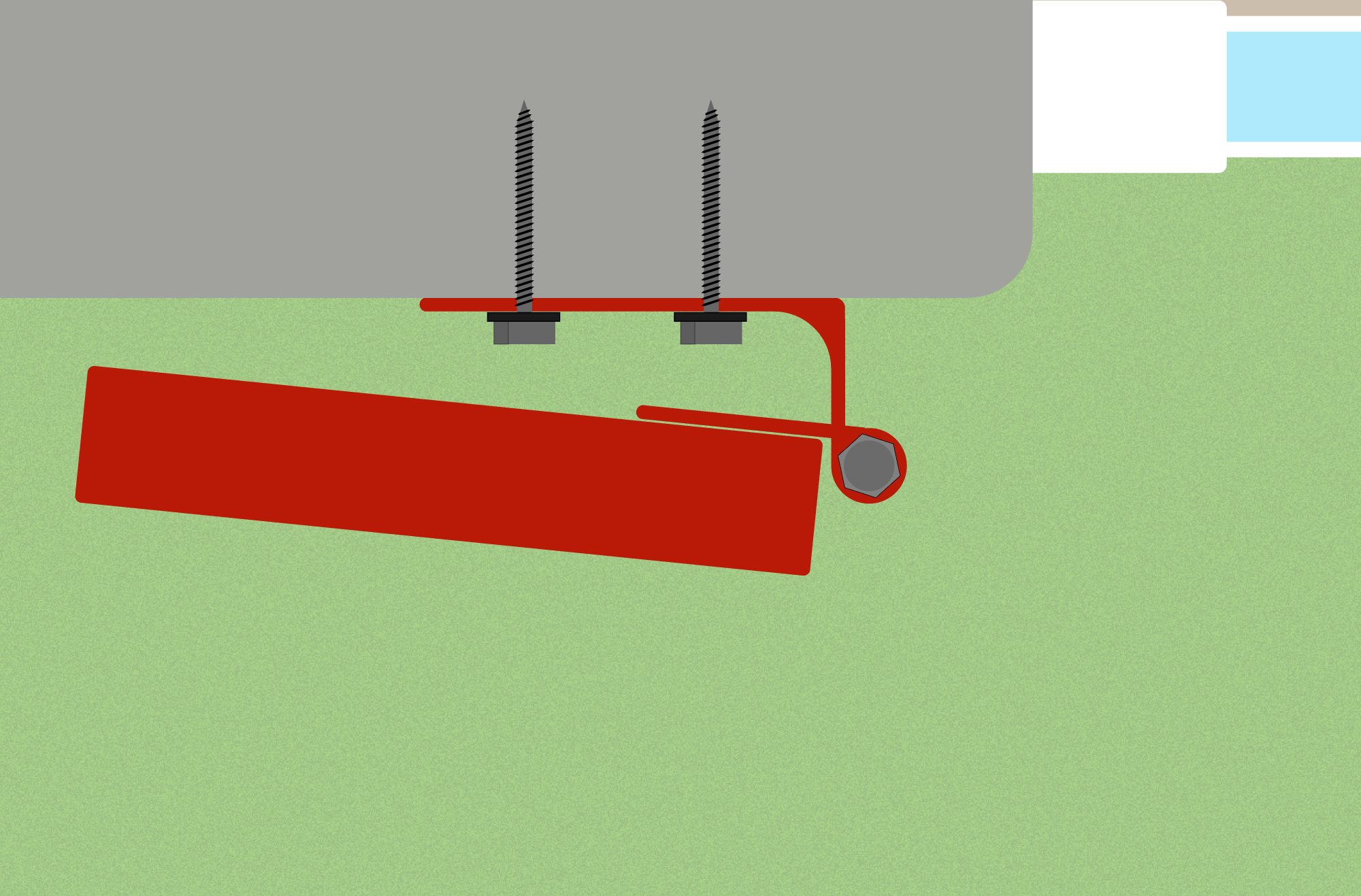

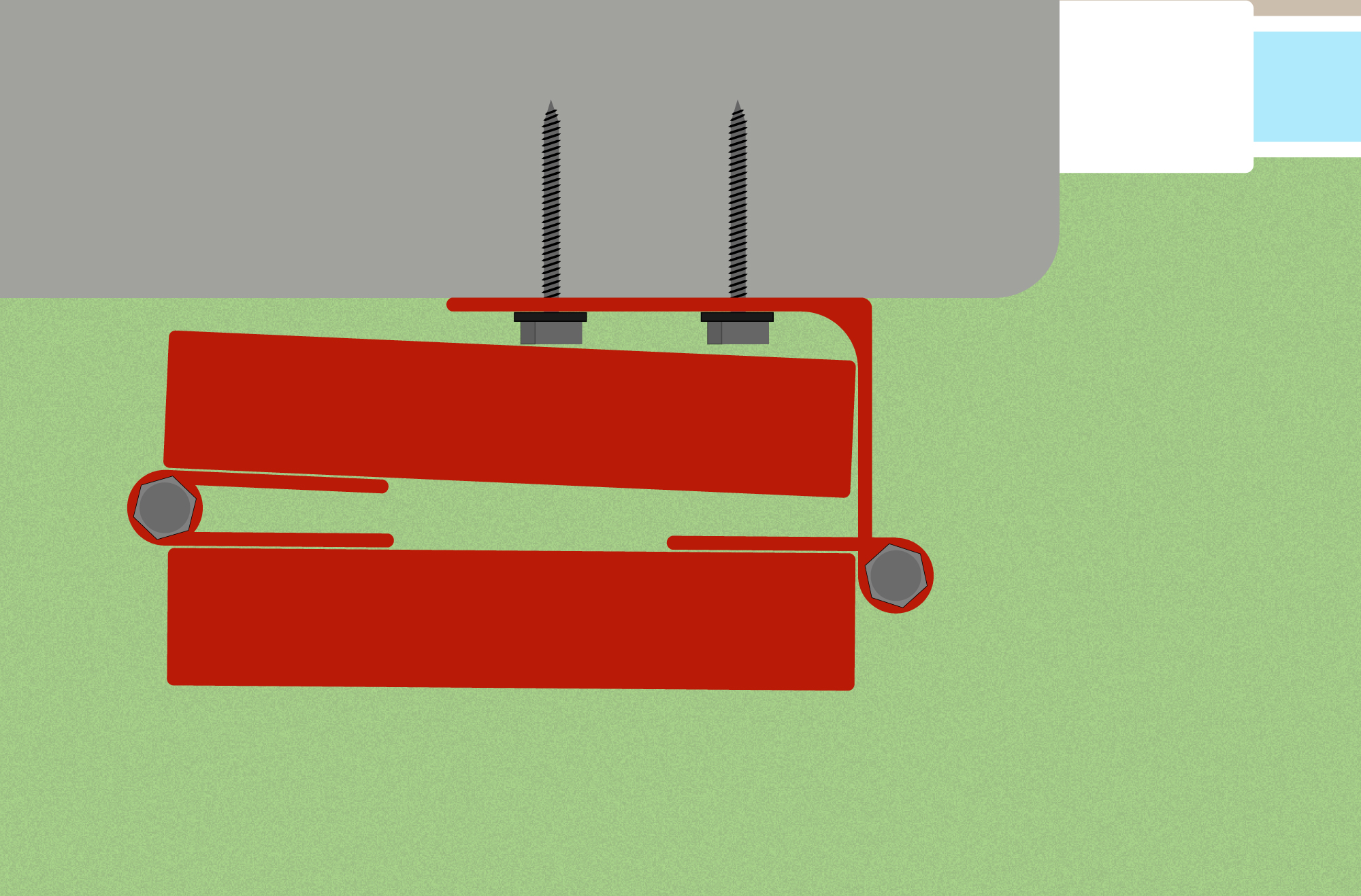

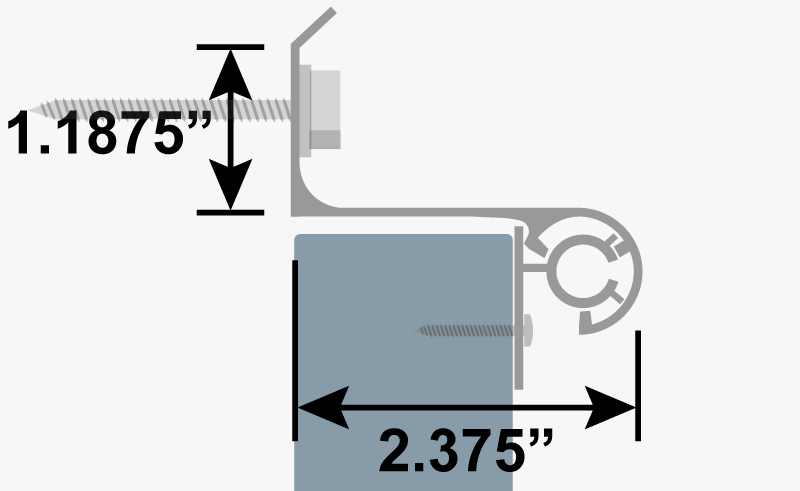

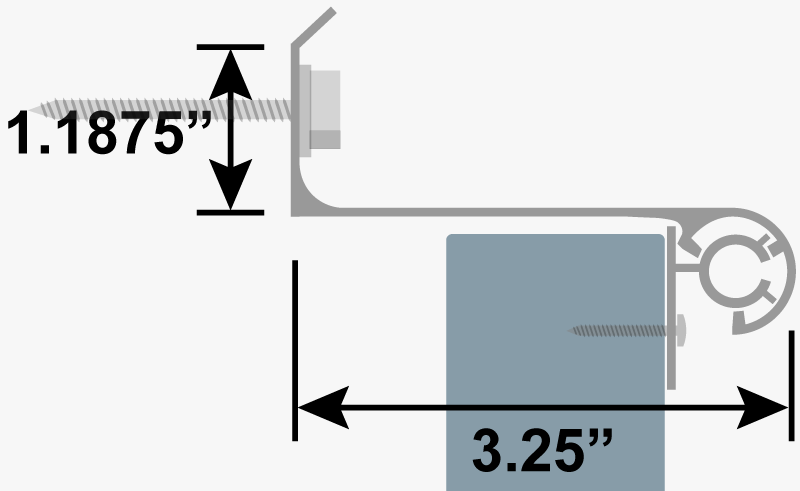

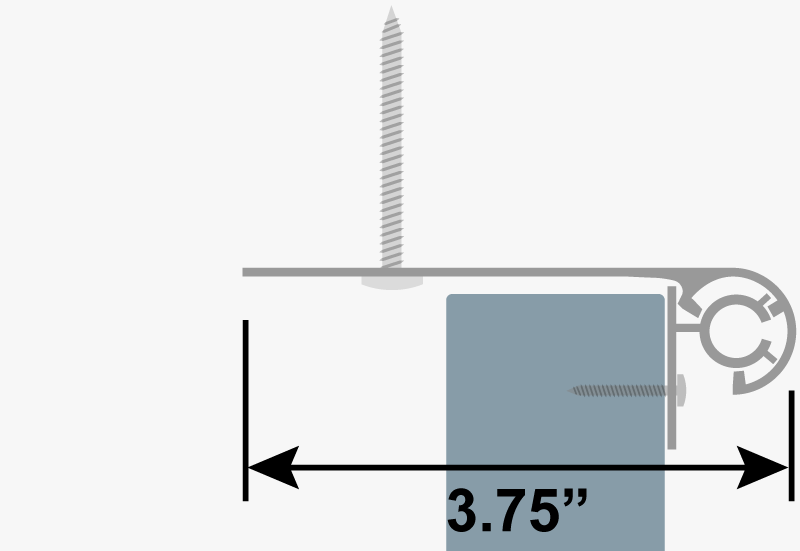

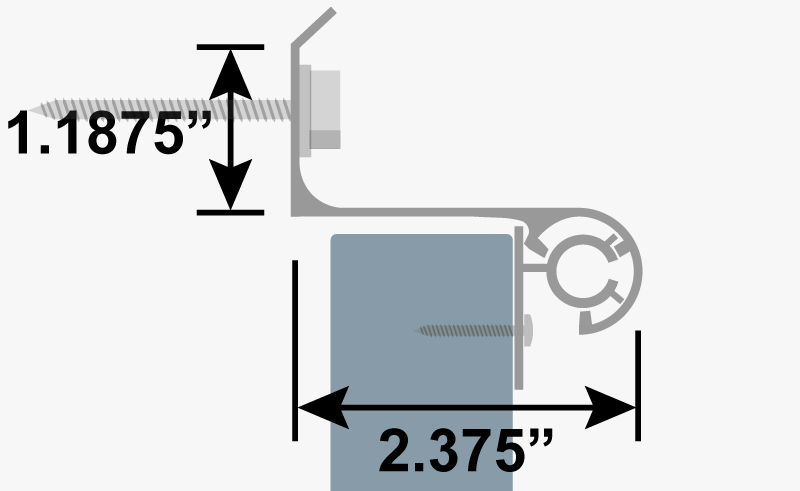

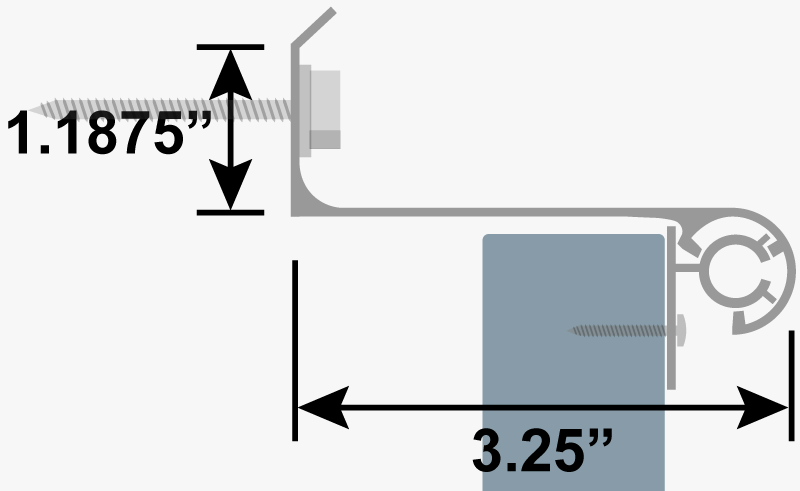

Composite Shutter Hardware

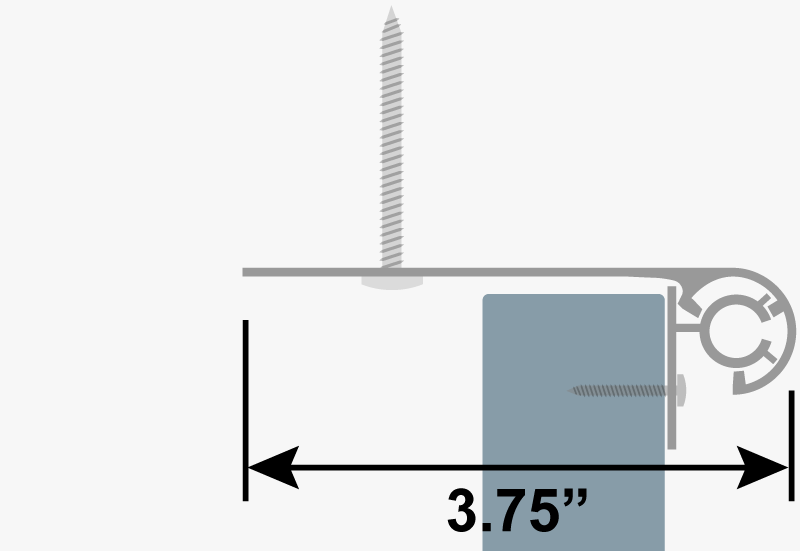

Composite shutters are shipped with Polycarbonate v-shaped fixed mounting brackets for an easy and secure installation. The vertical side of the bracket attaches to the building and the perpendicular side screws to either the top or bottom of the shutter. The brackets extend the full width of the shutter and are not easily visible after installation. The brackets are not pre-attached. Composite shutters are not compatible with other installation methods.

Install Composite Shutters

Construction of Louvered Composite Shutters

The material ShutterLand uses to manufacture exterior composite shutters is called Extira. This engineered wood product is similar to high-density fiberboard, but it is manufactured to be especially durable in outdoor applications where humidity varies. It is twice as strong as traditional HDF and natural wood products. Extira is man-made from 90% sustainable wood fibers adhered with marine-grade resins. This impressive material arrives at the factory in large straight sheets which are cut into individual window shutter components.

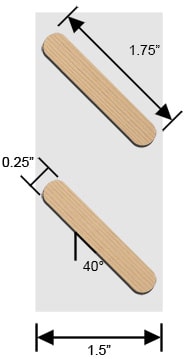

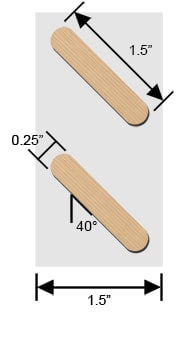

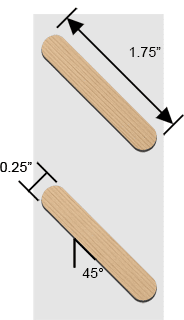

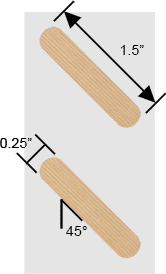

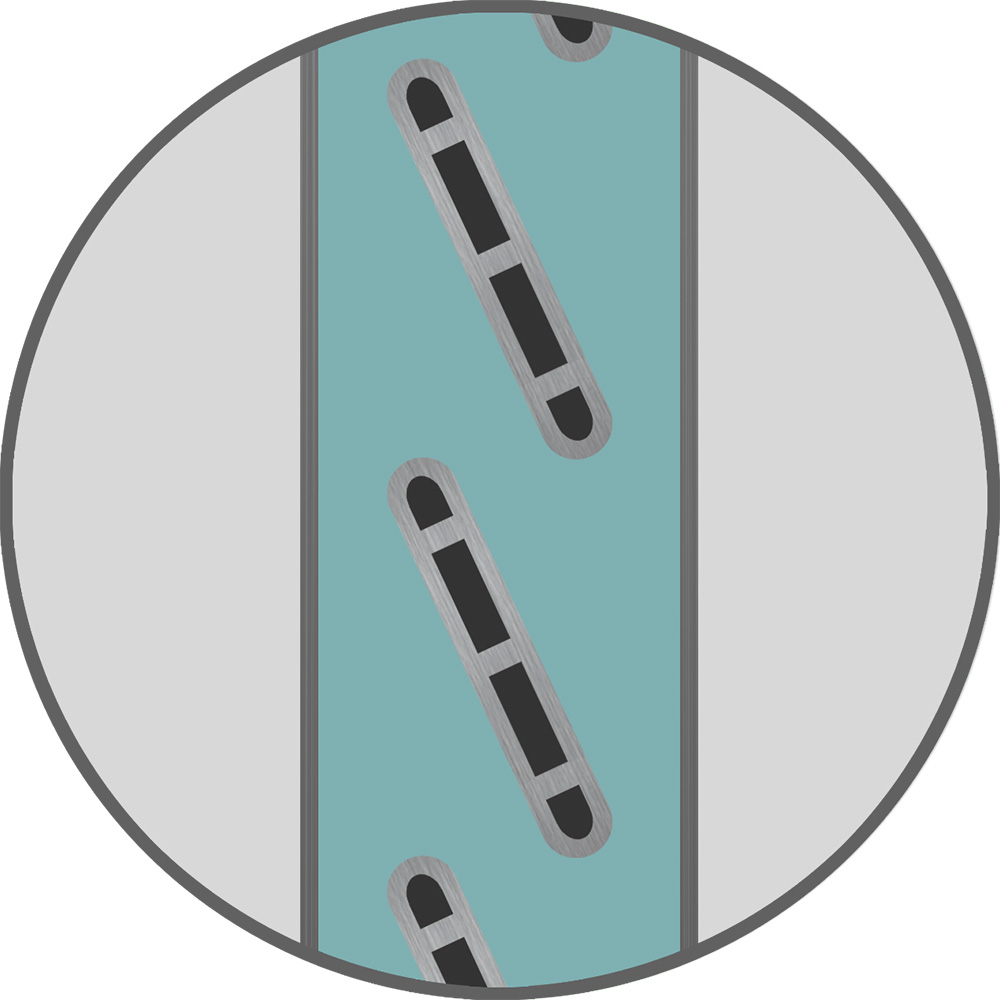

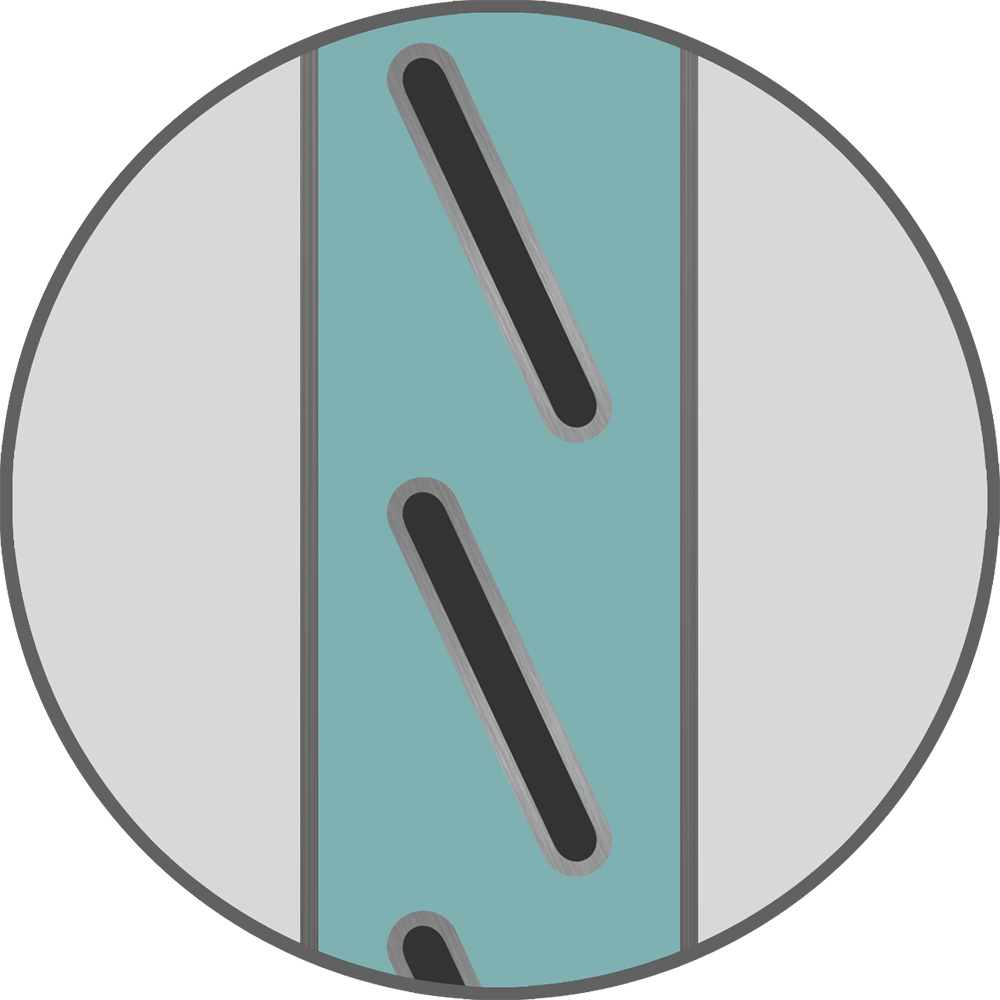

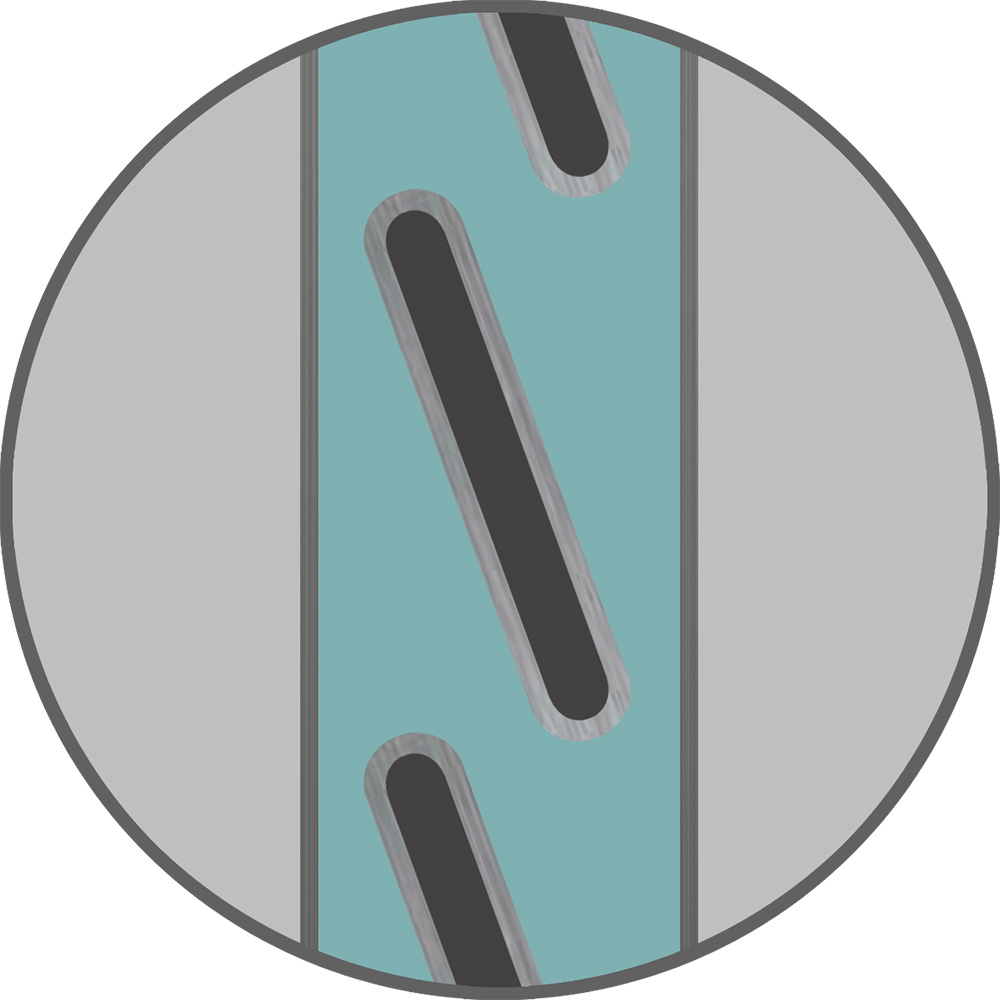

Louvered composite shutters are made to be 1 ¼” thick, with side stiles at 2 ½” wide. Two louver sizes are available; 1” louvers at a 20° angle and 1 ¾” louvers at a 10° angle. Top rails, divider rails and bottom rails have a standard height of 2 ½”. After components are cut to the custom size requested, they are assembled with tongue and groove joints, industrial exterior glue and 1” staples for extraordinary stability.

There is no space between louvers of composite shutters like those constructed from wood. The lack of space between louvers generally is not a distraction for most applications. Exterior composite louvers cut on a diagonal expose the embedded wood fibers that can cause the surface to become rougher than the face. This standard characteristic is universal and unavoidable. Sanding causes wood fibers to dislodge, resulting in more craters. Filling with wood putty results in an inconsistent patchy complexion, which is also not desirable. The texture difference is noticeable when handling the shutters but generally imperceptible after they are installed.

Historic renovation projects likely stipulate the use of natural wood louver shutters or louvered PVC shutters and restrict the use of composite panels.

Pros

+ Virtually impervious to moisture

+ Solid material

+ Do not expand and contract

+ Realistic appearance

+ Low-maintenance

+ Priced less than premium wood

+ Full range of sizes available

+ Unlimited paint colors

+ Long life expectancy

+ Fixed installation brackets included

+ Free shipping for most sizes

Cons

– Heavier than wood

– Detail on front side only

– Cannot be installed with hinges

– Louvers can have a rough cratered surface

– Cannot be stained

Installation of Louvered Composite Shutters

Composite louvered shutters should be installed in a stationary position with the polycarbonate brackets included. Installation using any method other than with the fixed brackets will void the warranty. Composite shutters are heavier than wood shutters and require proper support. The back of louvered composite shutters is flat without louvered detail, but will not be seen when installed against the building. The standard position of composite louvers is “down” to best repel water away from the structure. We do not recommend installing composite louvered shutters with louvers in the “up” position. Because composite louvers do not have space between them, there is potential for water to sit on the grooves, diminishing the lifespan of the shutters.

Occasionally, faux hinges or shutters dogs are used with stationary panels to accentuate the shutters. A faux vertical tilt bar can be selected to further accent the louvers.

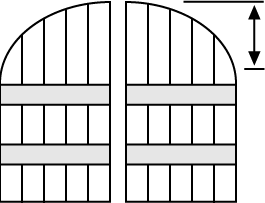

For windows with a rounded top, we offer arch top shutters. They are ordered as individual shutters, with either a left or right arch, which are not interchangeable. The dimensions of the arch can be a 1:1 ratio, for a perfect round shutter, in which the radius of the arch equals half of the window width. Or a custom configuration can be specified by providing the desired springline dimension. Review details about measuring for arch top shutters before ordering.

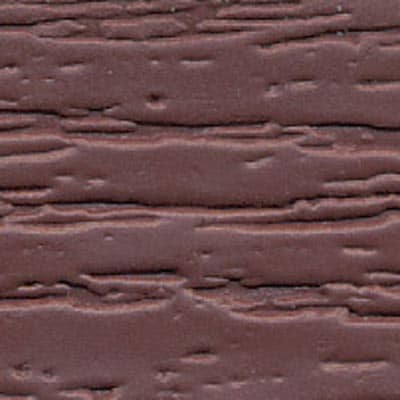

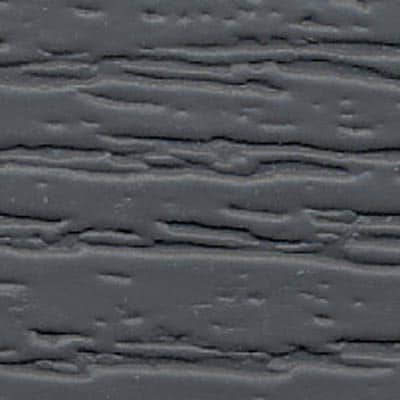

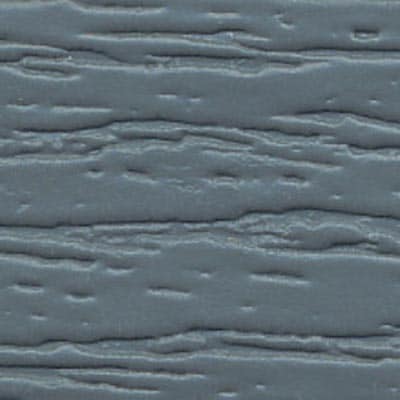

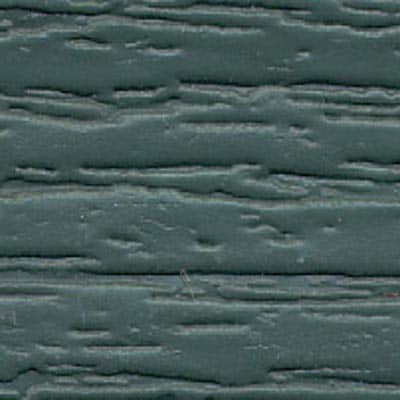

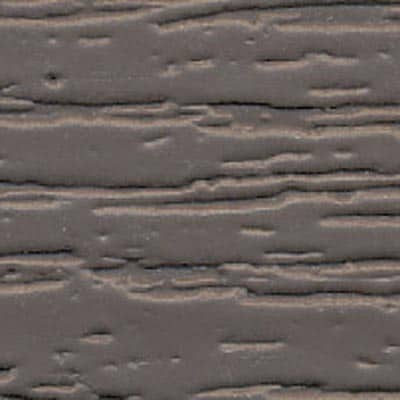

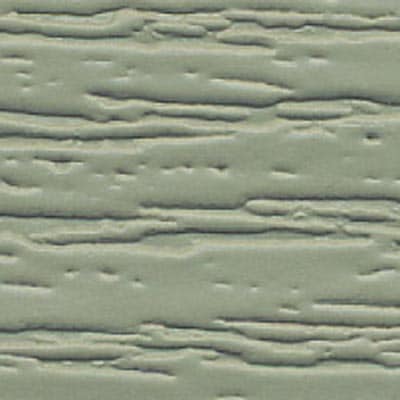

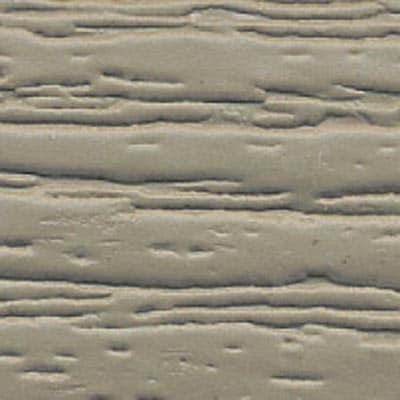

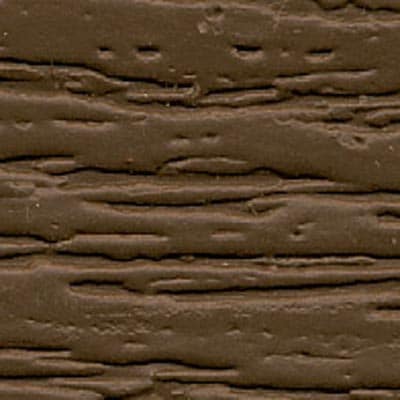

Louvered Composite Shutter Colors

Painting composite louvered exterior shutters both protects and adds visual appeal. Composite shutters are available to be shipped as unfinished, primed, or factory painted panels. Composite shutters cannot be stained because the material will not absorb the finish.

If composite louvered shutters are ordered unfinished, they need to be primed and painted on site. This is sometimes preferred for DIY projects with multiple exterior elements that can be finished at the same time. A solvent-based or water-based primer can be used, which will adequately bond with the composite shutter material. Two or three coats of primer, with a light sanding between coats, should result in a smooth, sealed surface, ready to accept paint.

After priming (whether at home or by the factory), lightly sand the surface with 220-grit sandpaper, then remove all fine dust with a tack cloth to ensure a clean surface. The Extira composite material finishes equally well with water-based or oil-based paint. A brush, roller or spray gun can all be equally efficient in applying the paint. We typically recommend two coats of exterior paint to ensure the shutters weather well. Consult with the paint manufacturer to locate a primer and paint that bond well together.

ShutterLand offers the option of ordering factory-painted louvered composite shutters. This is a great choice for homeowners who want to receive shutters ready to install right away. After fully priming and sealing the shutters, we professionally spray two coats of PPG Break-Through paint in a satin sheen. This paint is specially designed for excellent adhesion and gives uniform coverage for a long life in outdoor conditions.

We have nine standard paint colors available based on the most popular colors selected for shutters – Charcoal Slate, Black, Black Forest Green, Chrome Green, Hamilton Blue, Country Redwood, Cottage Red, and Tudor Brown. If none of those options meet your needs, you may send us the name of a manufacturer and paint color you wish to match, and we will custom mix paint for an additional $200. White or light-base colors may require an additional $35 per shutter. The increased amount is applied because light-based colors are more difficult to apply than darker colors, and will be presented for approval before an order is processed.

Whatever options you choose, composite louvered shutters from ShutterLand will provide a remarkable addition to your home’s exterior. It’s hard to beat custom exterior shutters that are made to your requested size and shipped to your door in about 4-6 weeks. Louvered composite shutters will give character and style for many years to come.