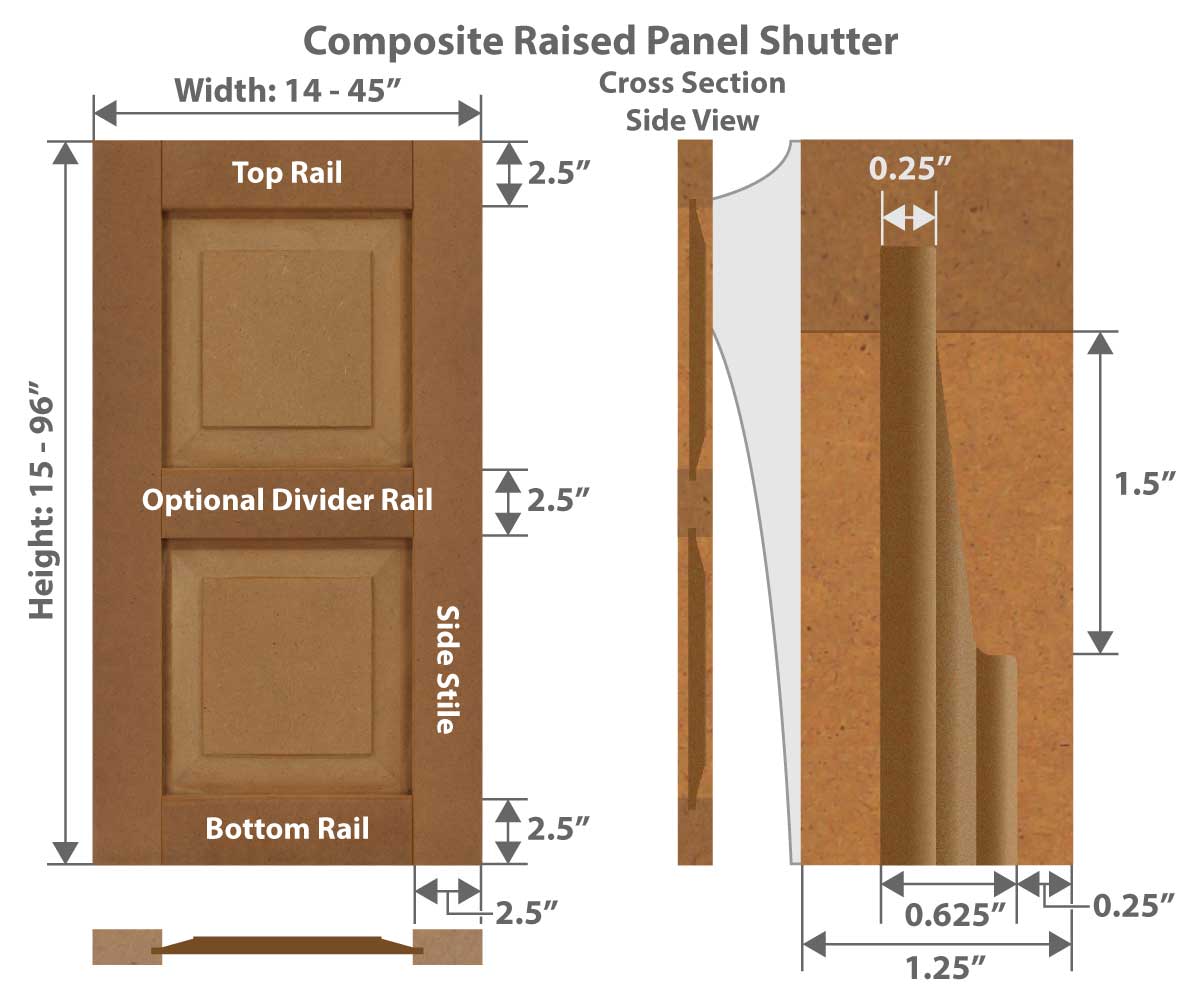

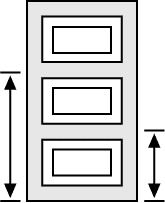

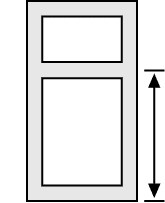

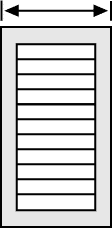

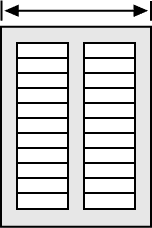

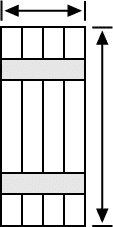

- Width

14 – 45″ in 0.25″ increments

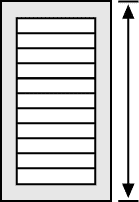

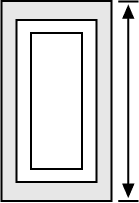

- Height

15 – 96″ in 0.25″ increments

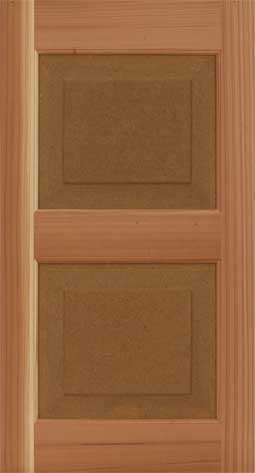

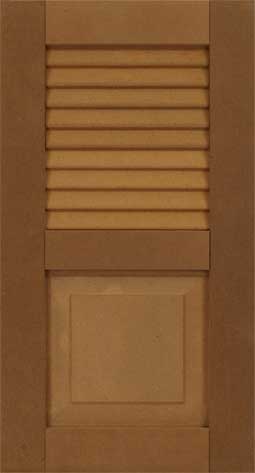

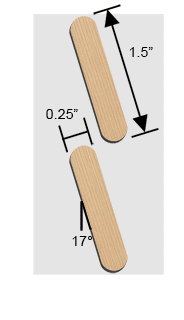

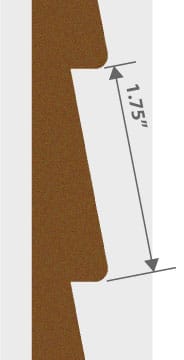

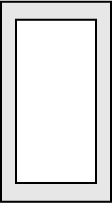

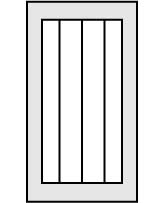

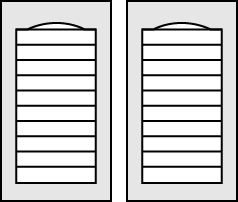

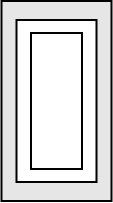

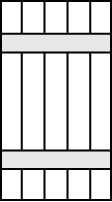

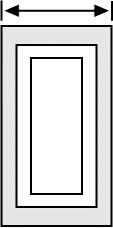

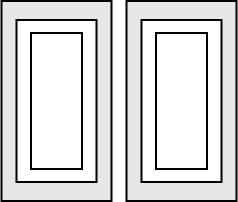

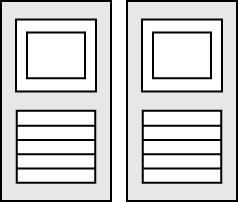

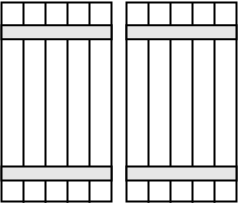

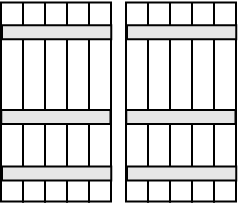

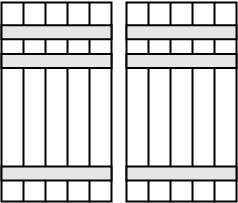

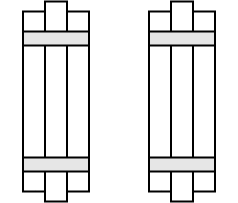

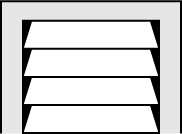

- Raised Panel

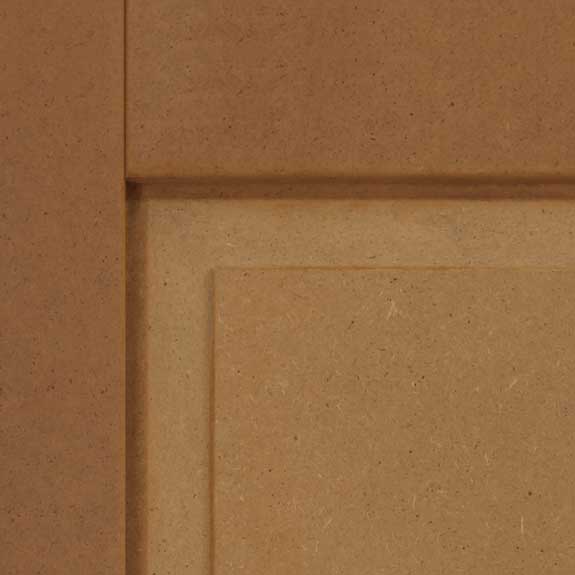

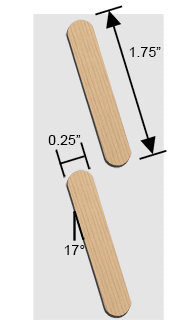

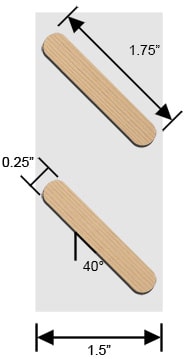

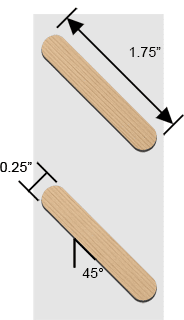

0.625” thick raised panel

0.25″ thick outside edge

1.5” wide beveled edge @ 11°

Flat on back of shutter

Shape cutout on request (+$) - Side Stiles

2.5″ wide

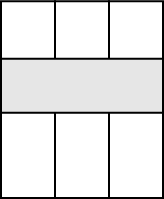

- Top Rail

2.5″ height

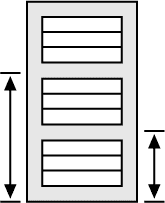

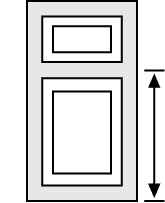

- Divider Rail

2.5″ height

Optional under 70″

Division Point: Bottom of shutter to center of divider

Second divider rail available - Bottom Rail

2.5″ height

- Shutter Depth

1.25″ thick

- Spec Sheet

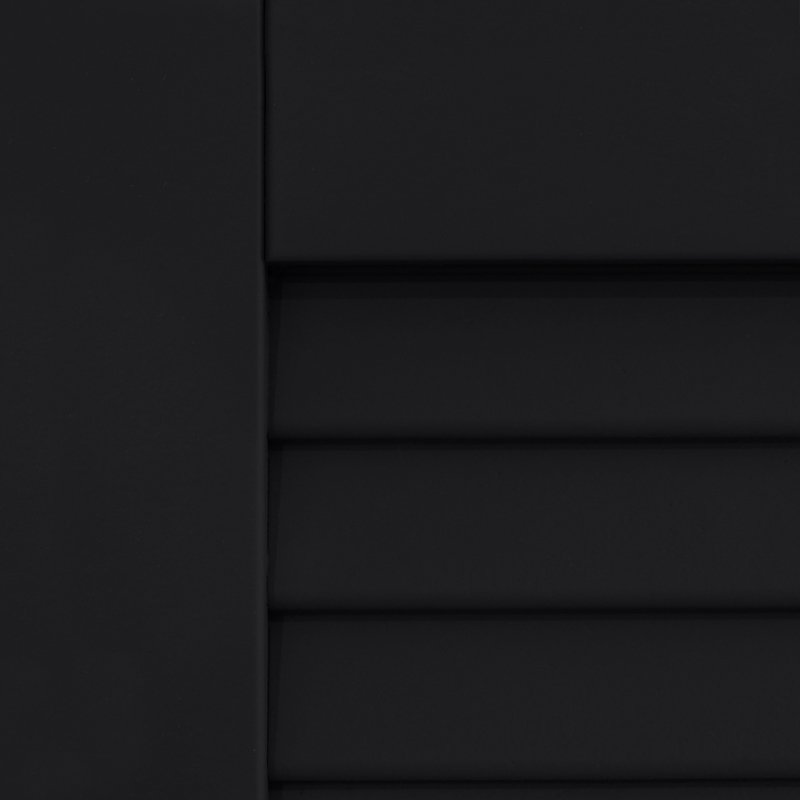

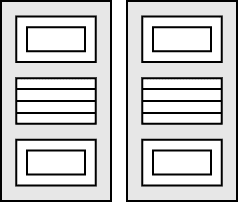

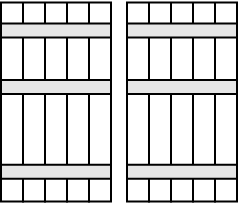

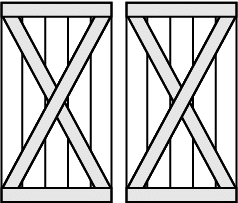

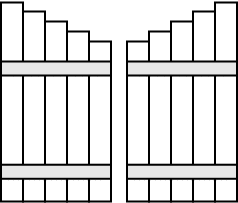

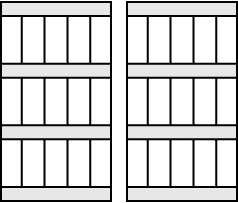

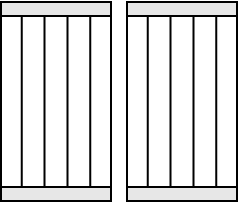

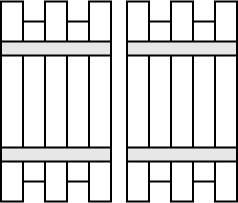

Composite Solid Panel Shutters

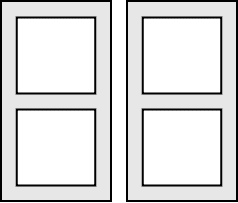

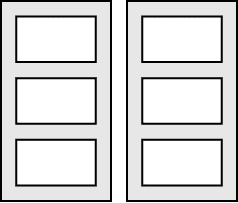

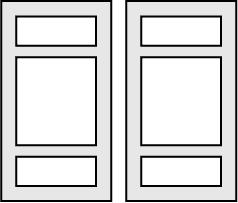

Raised Panel – Shaker Panel – Flat Panel

The width and height are available in 0.25” increments. Shutter sizes should be proportional to the window opening and determined by the allowable installation area.

Read More

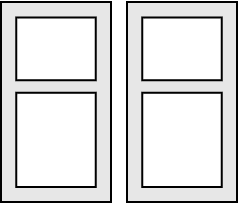

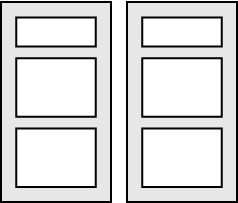

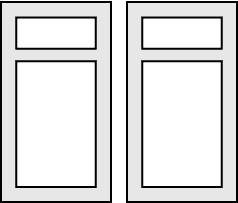

The central solid panel is offered in three designs: raised panel, flat panel or shaker panel. Each adds a different characteristic.

Read More

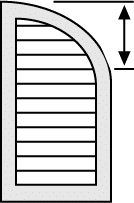

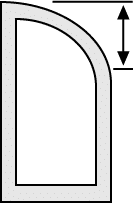

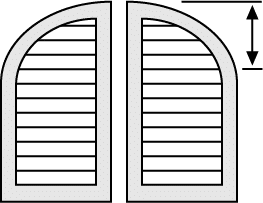

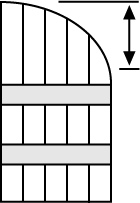

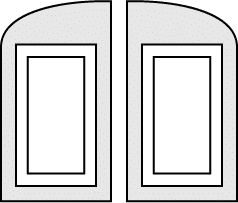

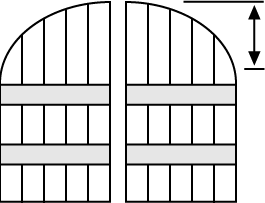

Most shutters are made with a straight horizontal top. Arch top shutters require a springline measurement from the top of the shutter to the start of the arch.

Read More

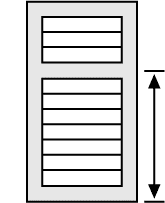

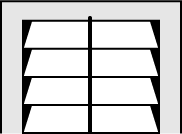

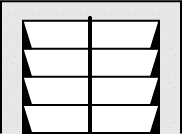

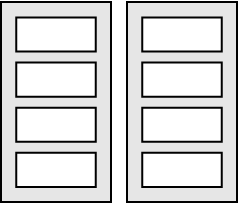

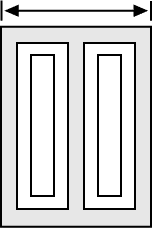

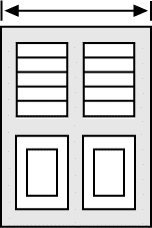

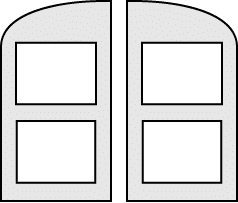

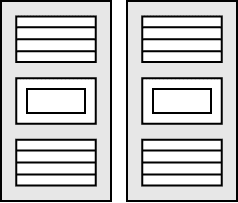

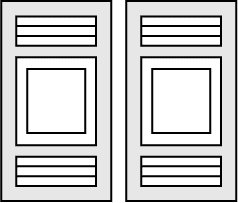

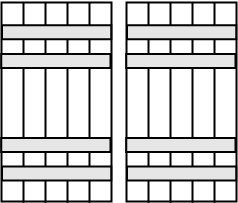

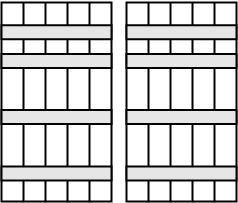

A horizontal divider rail creates multiple paneled sections. Shutters don’t require a divider rail but one or two can be added for interest. A “division point” is needed for custom locations.

Read More

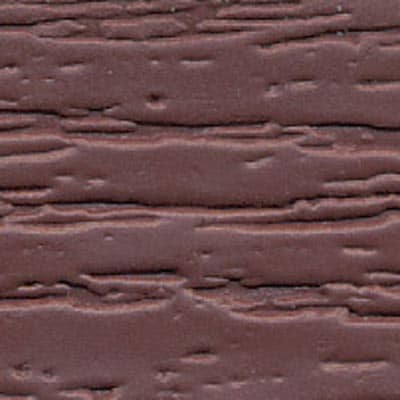

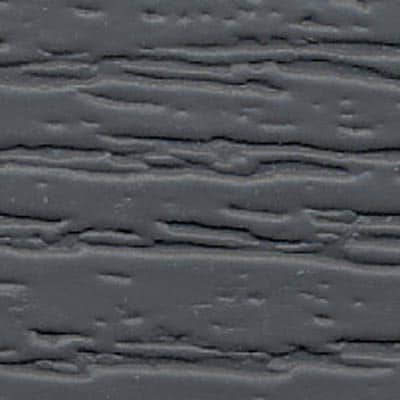

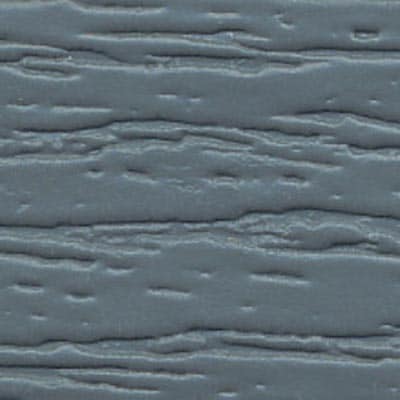

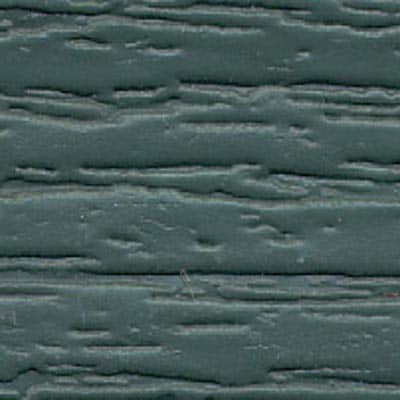

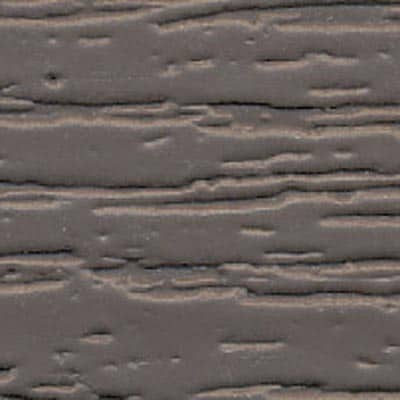

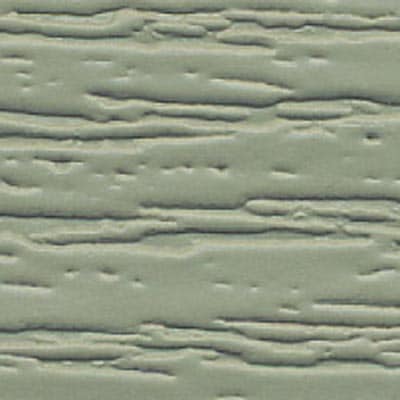

Specify unfinished, primed only or a fully primed and painted finish. Choose from nine standard paint colors or unlimited custom colors.

Read More

View Colors

Description

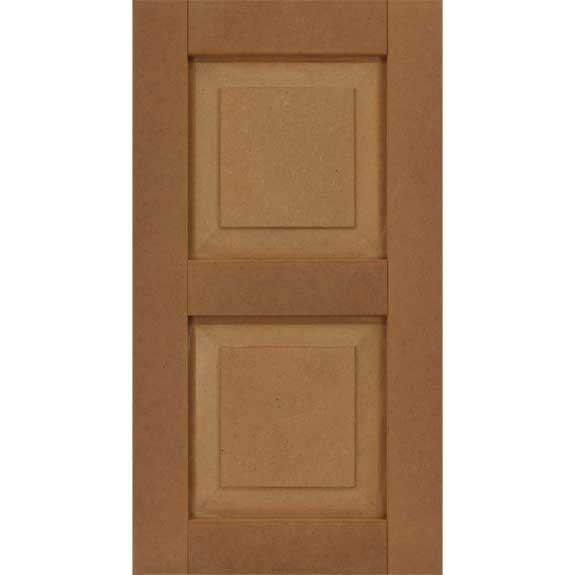

Composite solid raised, shaker and flat panel shutters are crafted for superior performance and exceptional beauty. Each solid panel shutter is built to the quarter inch in both width and height to best fit the designated window. One or two divider rails can be added at specified locations for a truly customized appearance. Select from nine standard colors or an unlimited selection of custom paint colors to match the existing palette. Exterior composite flat, shaker and raised panel shutters are constructed from Extira™, a solid pressed durable material designed to be impervious to moisture, rot, and termites, ensuring an extremely long life.

Dimensions

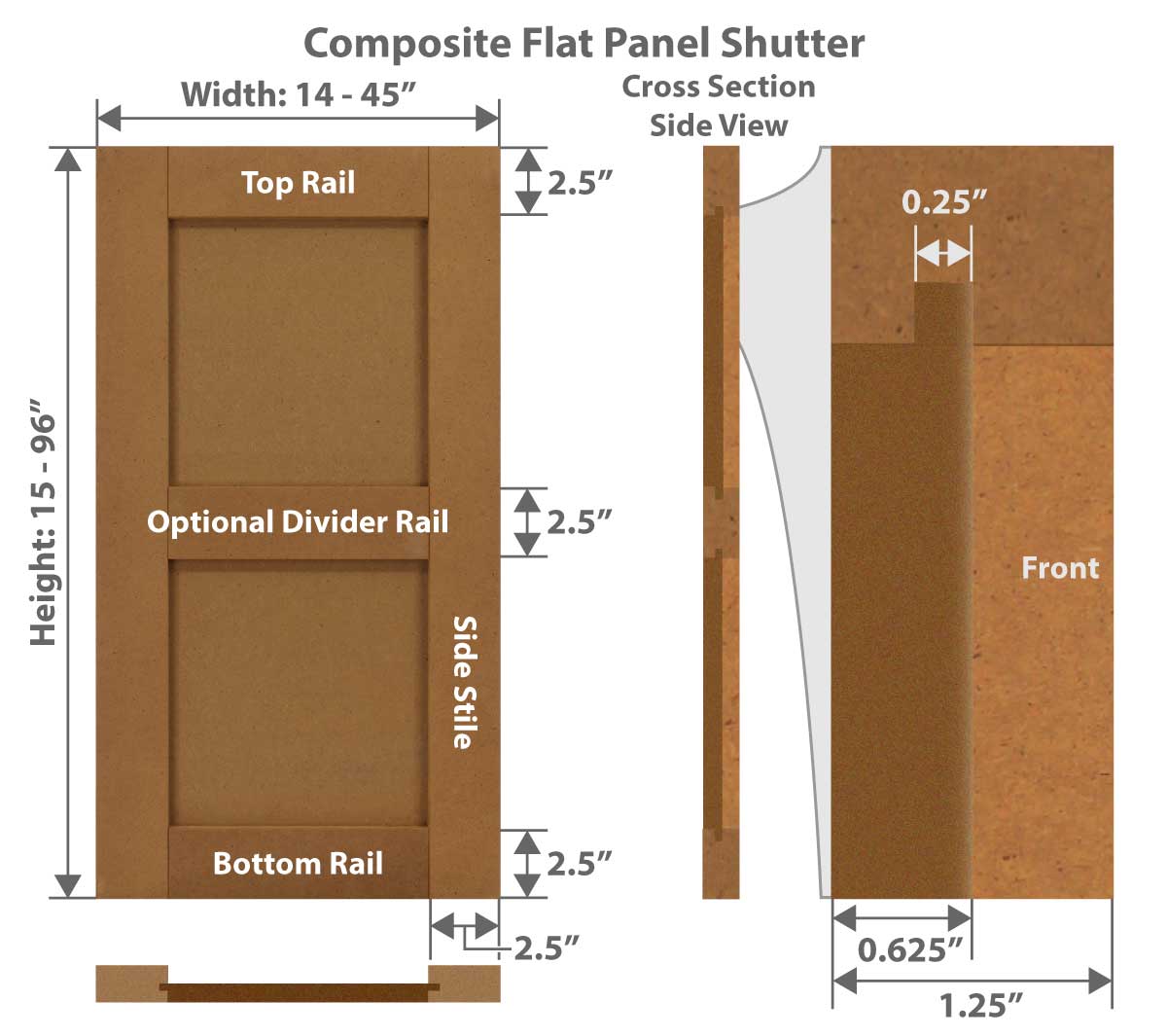

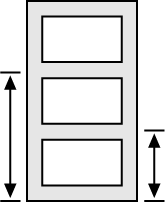

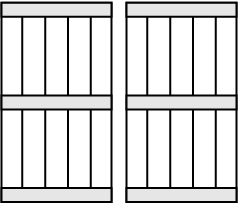

- Width

14 – 45″ in 0.25″ increments

- Height

15 – 96″ in 0.25″ increments

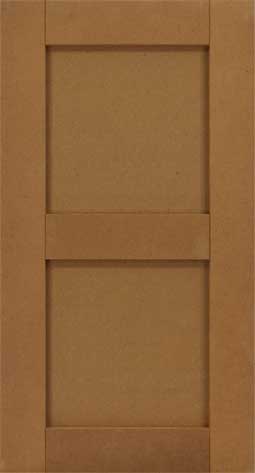

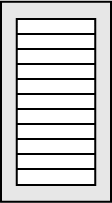

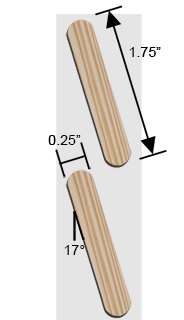

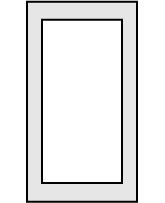

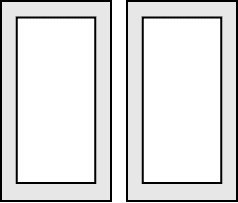

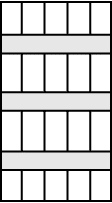

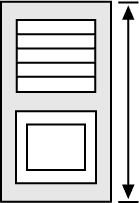

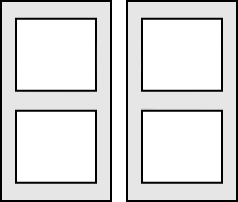

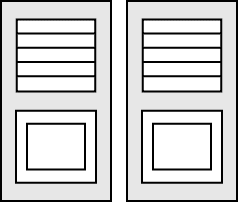

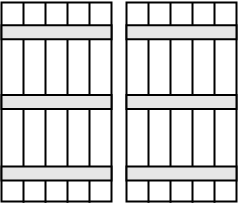

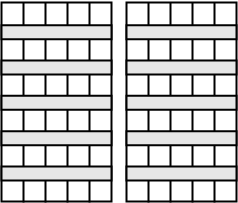

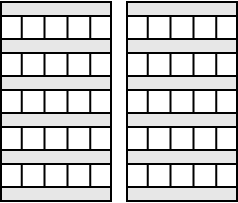

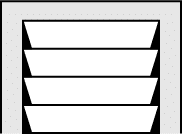

- Flat Panel

Material: Extira composite

0.625” thick

Flat on back of shutter

Shape cutout on request (+$) - Side Stiles

2.5″ wide

- Top Rail

2.5″ height

- Divider Rail

2.5″ height

Optional under 70″

Division Point: Bottom of shutter to center of divider

Second divider rail available - Bottom Rail

2.5″ height

- Shutter Depth

1.25″ thick

- Spec Sheet

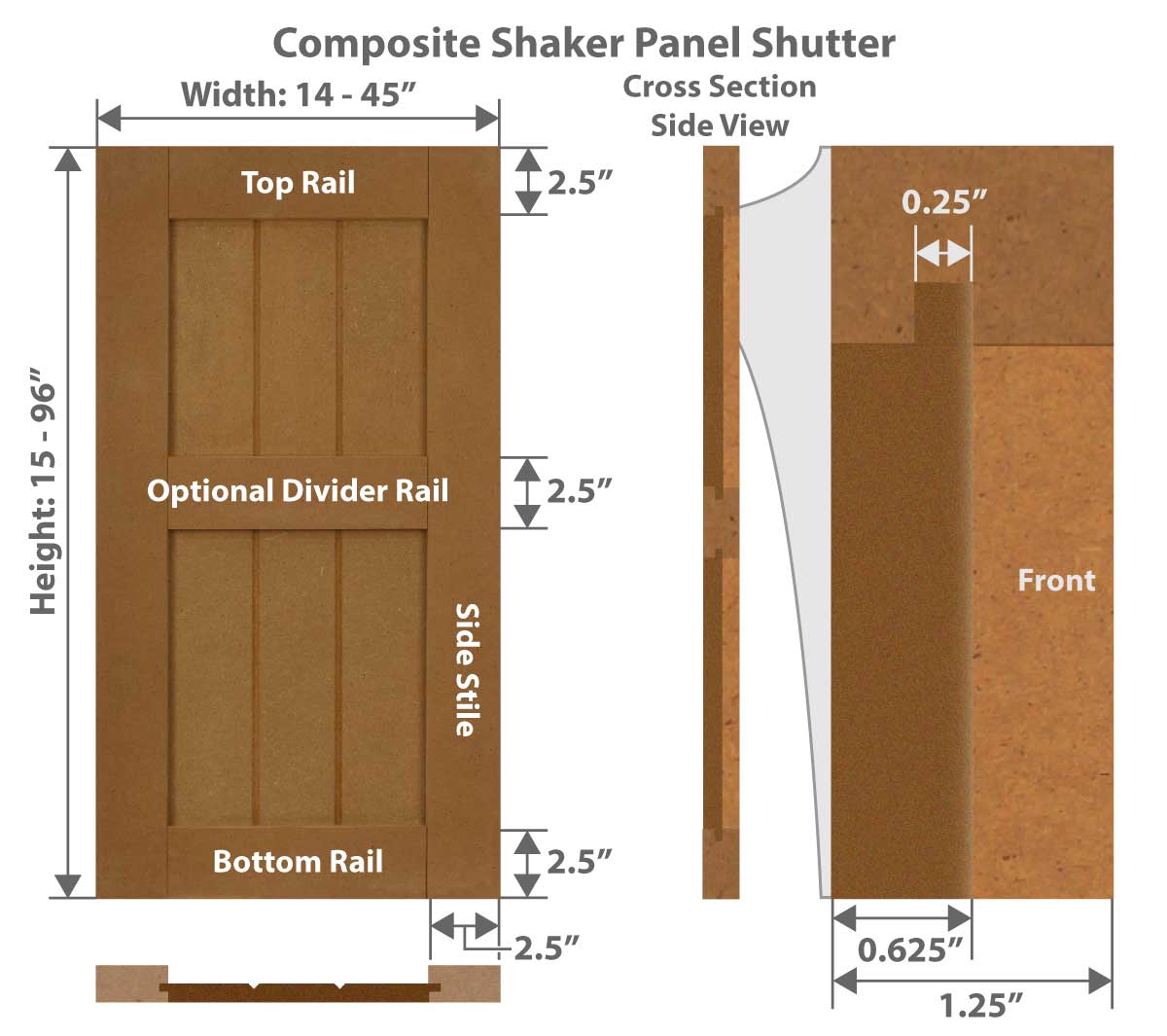

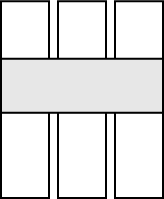

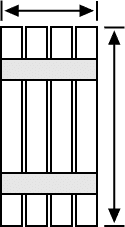

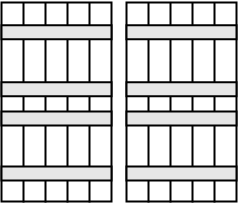

- Width

14 – 45″ in 0.25″ increments

- Height

15 – 96″ in 0.25″ increments

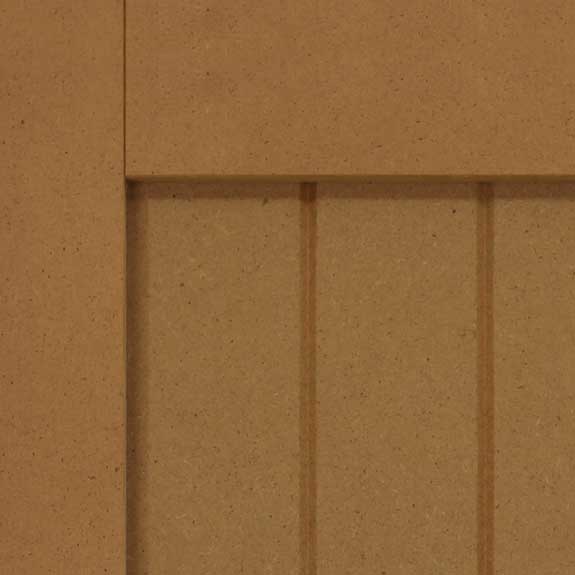

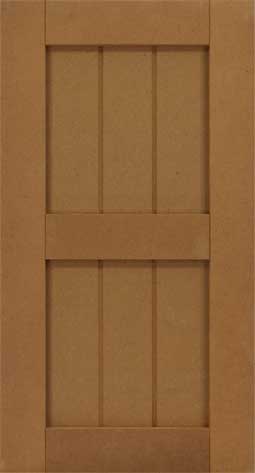

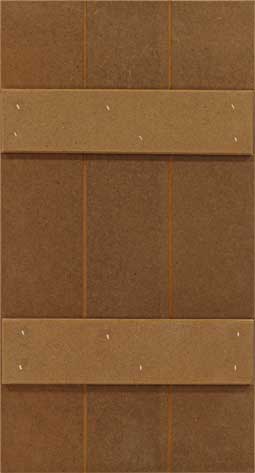

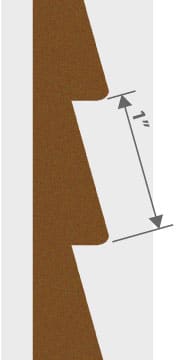

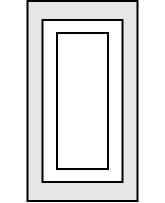

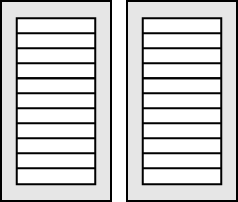

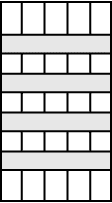

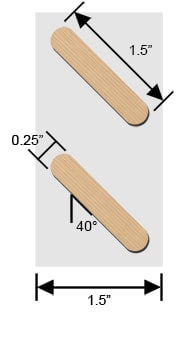

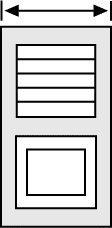

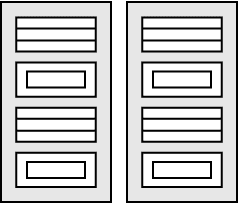

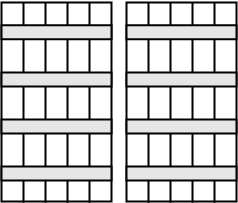

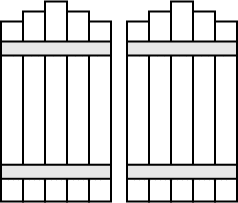

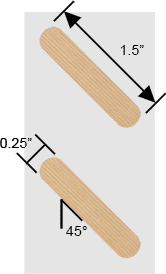

- Shaker Panel

0.625” thick

Shutter width:

2 grooves: 12” to 17.75”

3 grooves: 18” to 23.75”

4 grooves: 24” to 31.75”

5 grooves: 32” to 39.75”

6 grooves: 40” to 45”

Flat on back of shutter

Shape cutout on request (+$) - Side Stiles

2.5″ wide

- Top Rail

2.5″ height

- Divider Rail

2.5″ height

Optional under 70″

Division Point: Bottom of shutter to center of divider

Second divider rail available - Bottom Rail

2.5″ height

- Shutter Depth

1.25″ thick

- Spec Sheet

Detail

- Material

- Finish & ColorsStandard paint (9 colors)* Custom color (+$)* *Touch-up paint included Primed only Unfinished – Paint Grade Not stainable

- Assembly

Tongue & groove joints

Industrial exterior glue

& 1″ staples - Top Options

Straight

Arch top - Weight

Approximately 3.2 lbs per sq ft

- Production

Approximate Time: 4-6 weeks

- Warranty

- Measure

- Install

- Hardware

How to Measure

More informationHow to Install

More informationComposite Shutter Hardware

Composite shutters are shipped with Polycarbonate v-shaped fixed mounting brackets for an easy and secure installation. The vertical side of the bracket attaches to the building and the perpendicular side screws to either the top or bottom of the shutter. The brackets extend the full width of the shutter and are not easily visible after installation. The brackets are not pre-attached. Composite shutters are not compatible with other installation methods.

Install Composite Shutters

How Composite Solid Flat, Shaker and Raised Panel Shutters are Built

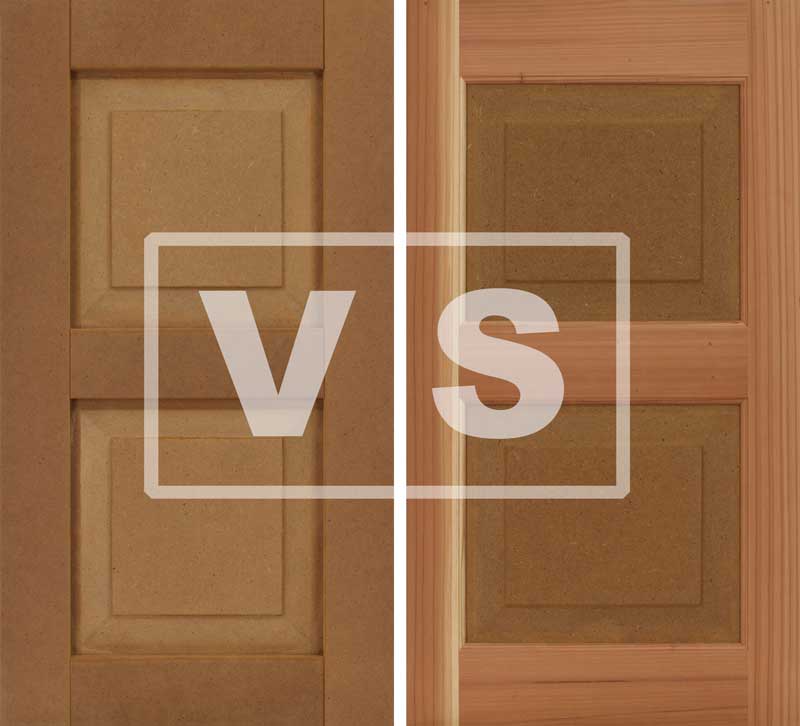

Construction begins with large sheets of Extira, an engineered wood product made from wood fibers compacted with marine-grade resins. Extira is specifically engineered for moisture-rich outside applications, and it is ideal for the construction of solid panel shutters. All-weather composite shutters are largely unaffected by extreme temperature fluctuation and variable humidity and is perfect for environments with these conditions. Extira does not expand and contract which prolongs the paint finish.

Individual components are milled and secured with industrial strength exterior adhesives and stainless steel staples. The stiles and rails are 1.25 inch thick and defining center panel is 0.625 inch thick. Extira composite shutters have been installed on homes in all 50 states across America.

Pros

+ Virtually impervious to moisture

+ Solid material

+ Do not expand and contract

+ Realistic appearance

+ Low-maintenance

+ Priced less than premium wood

+ Full range of sizes available

+ Unlimited paint colors

+ Long life expectancy

+ Fixed installation brackets included

+ Free shipping for most sizes

Cons

– Heavier than wood

– Detail on front side only

– Cannot be installed with hinges

– Cannot be stained

Stiles of Composite Solid Panel Exterior Shutters

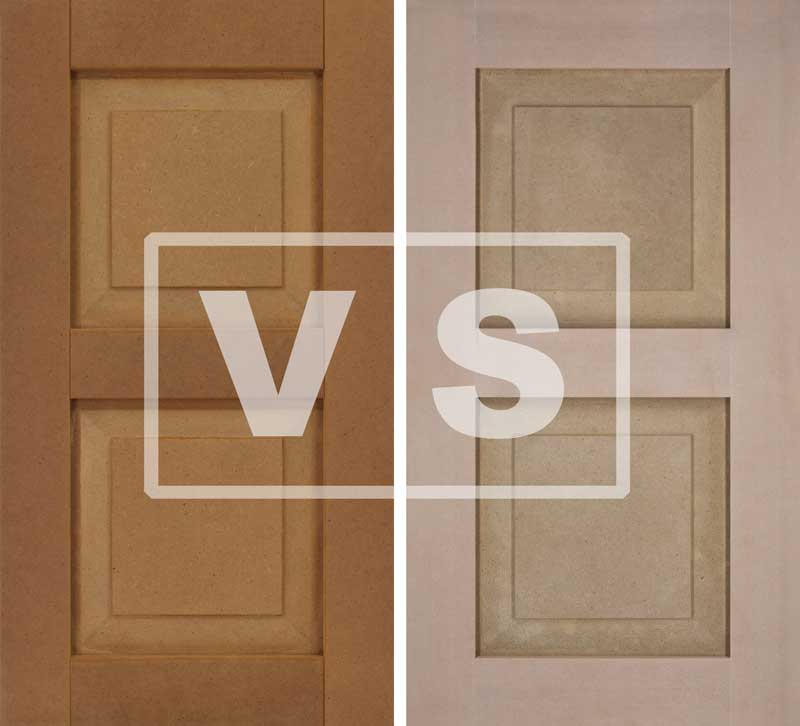

Solid panel composite shutters in all three designs are virtually indistinguishable from the same styles constructed from premium wood. These attractive exterior shutters are defined by the featured center solid panel. Choose from either a flat, raised or shaker panels.

Raised panel shutters are defined with a central plateau with beveled edges. The elevated plane produces an illusion of depth and captivates the eye. This iconic style has been used on American homes since Colonial times and is still widely utilized on new construction today. Traditional solid raised panel shutters are stylistically appropriate on Colonial, Georgian, and Plantation-Plain style homes. Historically, raised panel shutters were used for room darkening, privacy on the first story, severe weather protection and security from intruders in extreme situations.

The slant of composite raised panels cut on a diagonal exposes the embedded wood fibers that can cause the surface to become slightly rougher than the face. This standard characteristic is universal and unavoidable. Sanding causes wood fibers to dislodge, resulting in more craters. Filling with wood putty results in an inconsistent patchy complexion, which is also not desirable. The texture difference is noticeable when handling the shutters but generally imperceptible after they are installed.

The flat panel shutter is simple in composition with a modest, yet dignified, presence. This minimalistic conservative approach conveys a clean modern identity. Still, flat panel shutters add color, contrast and depth that other architectural elements or window treatments would be unable to achieve

A shaker panel shutter conveys the illusion of vertical boards flanked by an elevated perimeter. This variation of the exterior solid panel shutter is a refined board & batten approach popular on farmhouse and craftsman style homes.

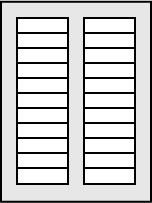

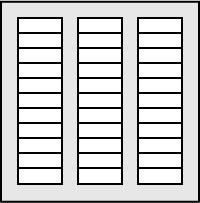

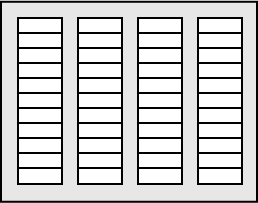

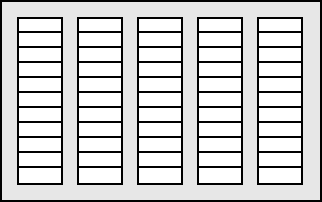

Configuration Options of Raised and Flat Panel Shutters

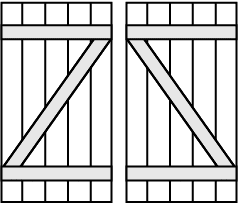

The top profile of a majority of outdoor solid panel shutters is flat and straight. However, arch top shutters are available with a curved top to mimic the lines of a rounded window. A springline measurement will need to be recorded to achieve the correct radius. Use the arch top measuring instructions for the best results.

A divider rail separates the shutter into top and bottom panel areas. The divider looks much like the top rail and is an optional. The use of two divider rails results in three solid panel areas. The divider rail location can be centered or placed at a custom location by providing the measurement from the bottom of the shutter to the desired center of the divider.

Solid Panel Composite Shutter Paint Colors

Composite raised, grooved and flat panel exterior shutters can be shipped unfinished, primed, or factory painted. The composite material can be difficult to properly prime, so is strongly recommend that they be ordered either primed or fully painted. Two or three coats of primer, with a light sanding with 220-grit sandpaper between coats, should result in a smooth, sealed surface, ready to accept paint.

ShutterLand has nine standard paint colors available based on the most popular hues selected for window shutters – Charcoal Slate, Black, Black Forest Green, Chrome Green, Hamilton Blue, Country Redwood, Cottage Red, and Tudor Brown.

Ordering factory-painted composite solid flat panel shutters is a great choice for homeowners who want to receive shutters ready to install immediately. After fully priming and sealing the shutters, we professionally spray two coats of Benjamin Moore Corotech COMMAND paint in a satin sheen. This paint is specially designed for excellent adhesion and gives uniform coverage for a long life in outside conditions.

Custom color matching is an option if none of the standard colors meet your needs. Provide the name and manufacturer of a color you wish to match and we will custom mix paint for an additional $200. White or light-base colors may require an additional $35 per shutter. The increased amount is applied because light-based colors are more difficult to apply than darker colors, and will be presented for approval before an order is processed.

On location DIY painting is relatively easy because of the large expanse of flat surface. The Extira composite material finishes equally well with water-based, oil-based or lacquer-based paint. Most paint stores will specify a combination of primer and paint that will be most effective. It is best to avoid an all-in-one combination paint-primer. A brush, roller or spray gun can all be efficient in applying the paint. We typically suggest two coats of exterior paint to ensure the shutters are well protected.

Composite shaker, raised and solid flat panel shutters cannot be stained because the material will not absorb the finish.

Installation of Composite Shutters

Composite shaker, raised or flat panel shutters should be installed in a fixed position. L-shaped polycarbonate mounting brackets are included with every composite shutter order to affix shutters in place so they will not move. The installation bracket is not preattached. Installation using any method other than with the fixed brackets will void the warranty. Composite shutters cannot be installed with functional hinges or hardware.

Composite solid panel shutters are heavier than traditional wood shutters with only one presentable side.

ShutterLand solid composite panel shutters are designed to enhance curb appeal. They provide an impressive architectural detail that will make a major impact. Composite raised, shaker and flat panel shutters currently require about 4-6 weeks for manufacturing. After completion, they are shipped direct to your front door.