Exterior Shutter Hinges Guide

ShutterLand exterior shutters are built to be functional. The strong sturdy construction becomes operable with the addition of exterior shutter hinges. Successful installation begins with the selection of the right type of exterior shutter hinges for the window. Multiple types of exterior shutter hinges are available for variable situations, which is best determined in the measuring phase.

How Exterior Shutter Hinges Work

All exterior shutter hinges are comprised of two independent parts that work in tandem. The pivot leaf of the exterior hinge anchors to the building creating a stationary axis point, that provides support to the mobile leaf. The mobile leaf screws to the exterior shutter and rotates on the pivot leaf pintle.

Surface Mount vs. Mortise Hinges

Exterior shutter hinges fall into two broad categories.

Surface mount hinges affix to the front (or in some cases the back) of exterior wooden shutters or PVC shutters and to the face of the window frame. Correctly sized exterior shutters do not need to be altered or modified to install with surface mount hinges. This type of hinge can position the shutters inside of a deep window opening or float them in front of a shallow recess.

Mortise hinges can only be used when PVC or exterior wood shutter fits inside of the window opening. This type of hinge nestles between the edge of the shutter and the window casing. A cavity, or mortise, on both surfaces needs to be cut with a router or chisel to the height and depth of one hinge leaf.

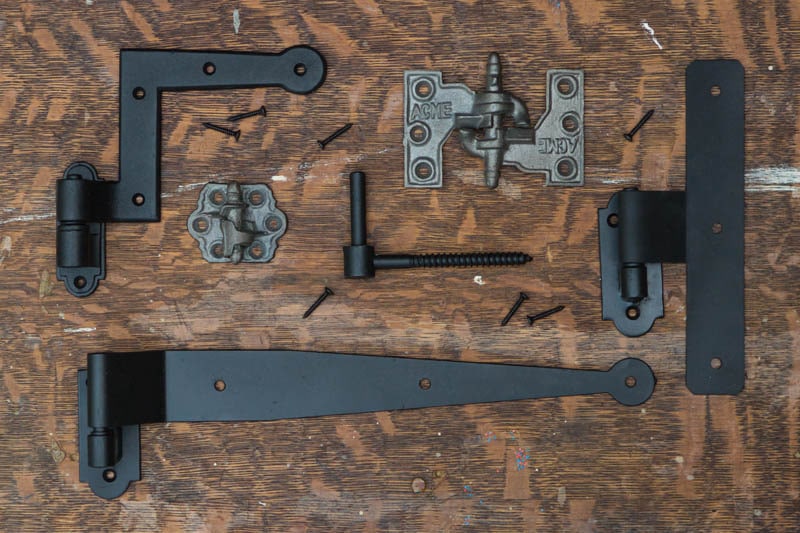

Popular Exterior Shutter Hinges

Horizontal strap hinges are widely used on homes throughout the country. Each hinge consists of two components. The long narrow band, which is available in various lengths, surface mounts to either the top, bottom, or divider rail of the shutter with screws. A separate up-pointing pintle is anchored to the front casing. One end of the strap will drop onto the pintle, while the opposite side is embellished with a circle, bean, or heart shaped end. Two hinges per shutter is often sufficient, but a third hinge may be necessary to support extremely large wood or PVC shutters. Strap hinges can be used to install exterior shutters inside of the window opening or floated just in front. The strap length should be at least 3 inches shorter than the width of the outside shutter. Standard strap hinges are not visible when the shutters are open. A reverse mount exterior strap hinge is configured to screw into the rear of the panel, making the exterior shutter hardware conspicuous when the panels are swung to either side. Shutter dogs, or other devices, are necessary to keep the shutters locked wide of the window.

L-style shutter hinges are a modified version of the long horizontal strap hinge. Also known as a New York style hinge, the L-shaped hinge can be used for narrow shutters, to achieve an improved pintle mounting location, or simply for visual preference.

Vertical strap hinges are often employed when a third center support hinge is necessary and a divider rail is absent. Vertical strap exterior shutter hinges are less popular as a primary style than the horizontal strap and L-style hinges.

Clarks Tip hinges surface mount with one leaf screwing to the outward portion of the casing and one to the front of the closed shutter panel. These adjacent surfaces must be on the same plane. When open, the hinge is well hidden and fully clear of the window. They employ an ingenious design to dependably lock in an open position. A slight elevation of the shutter permits the panel to swing closed. The hinge can be separated by fully lifting the shutter side leaf from the pintle side mounted on the casing.

The Acme Lull & Porter hinge performs in similar fashion to the Clarks Tip hinge, except it must be mortised to fit between the shutter stile and casing side. The Lull & Porter is the oldest style of exterior shutter hinges and is still widely employed.

Less ornate edge mortise hinges are available for more contemporary applications. These butt hinges do not lock in place like the Lull & Porter style.

Shutter Hinge Considerations

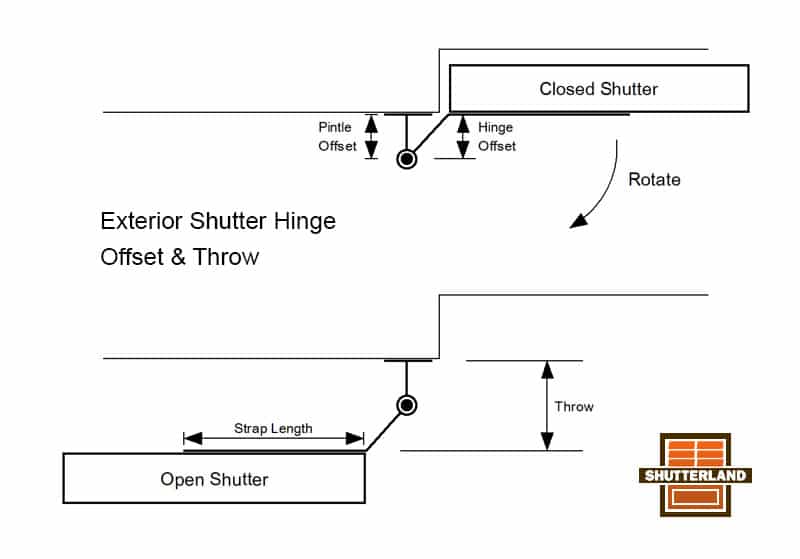

Exterior Hinge Offset and Throw

The pintle offset measures from the plate mounting surface to the cylindrical pivot point. The hinge offset dimension is from the shutter face to the same pivot point. Typically the hinge strap and pintle offsets are the same. However, it is possible for the hinge strap to have a different offset than the pintle, sometimes referred to as a “New Construction” hinge.

Throw is equal to the sum of the strap and pintle offsets. Throw essentially defines the distance from the base of the pintle to the back of the shutter when open. A larger throw is needed when the mounting surface is recessed behind the siding facade.

Lag Mount and Plate Mount Pintles

Plate mount pintles adhere to flat wooden surfaces best. Three or four screws secure the back plate in place. Substitute lag mount pintles to penetrate uneven or hard materials. Lag mount pintles are manufactured with a long bolt for a single entry point. The variable self-adjusted offset of a lag mount pintle depends on the depth tightened. Prepare wood casing with a pilot hole. Brace to brick or masonry supports with a pre-drilled hole in conjunction with a lag shield anchor.

Outdoor Hinge Materials

Exterior shutter hinges are sold in two primary materials. Traditional galvanized cast-iron hinges are true to historic period construction. Powder coated stainless steel hinges have a slightly more refined profile while offering maximum strength. Both materials are incredibly resilient and astonishingly attractive.

Exterior Shutter Hinge Installation Location

The vertical portion of strap and L-style exterior shutter hinges should align with the center of the top and bottom rails. A third hinge is typically secured in line with the divider rail. If there is no divider rail, the additional hinge generally positions on the vertical middle. The top of a mortise hinge or Clarks Tip hinge commonly aligns with the bottom of the top rail. Likewise, the bottom of the second hinge will rest in line with the top of the bottom rail.

Hinges on Vinyl Shutters

People commonly ask, “Can you put hinges on vinyl shutters?” The answer is “No.” Vinyl shutters are hollow and do not have a back. Therefore, they are not sturdy enough to independently support themselves and cannot accept the installation screws. Vinyl shutters install with spikes or screws in a fixed position for decorative purposes only.

Composite shutters also cannot be installed with functional hinges. Composite shutters are shipped with fixed mounting brackets to secure the panels in place.

To simulate the appearance of authentic hardware, decorative faux hinges can be attached to vinyl shutters.